电线

Magnet wire

Magnet wire

电线

1.漆包線的命名及特性

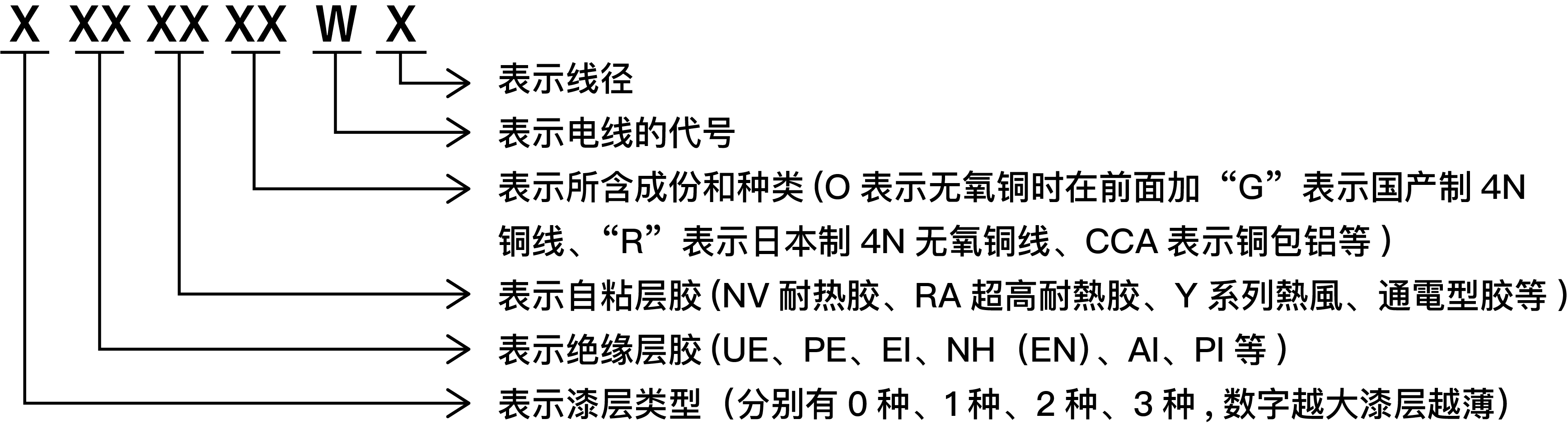

1.漆包线型号的命名法:

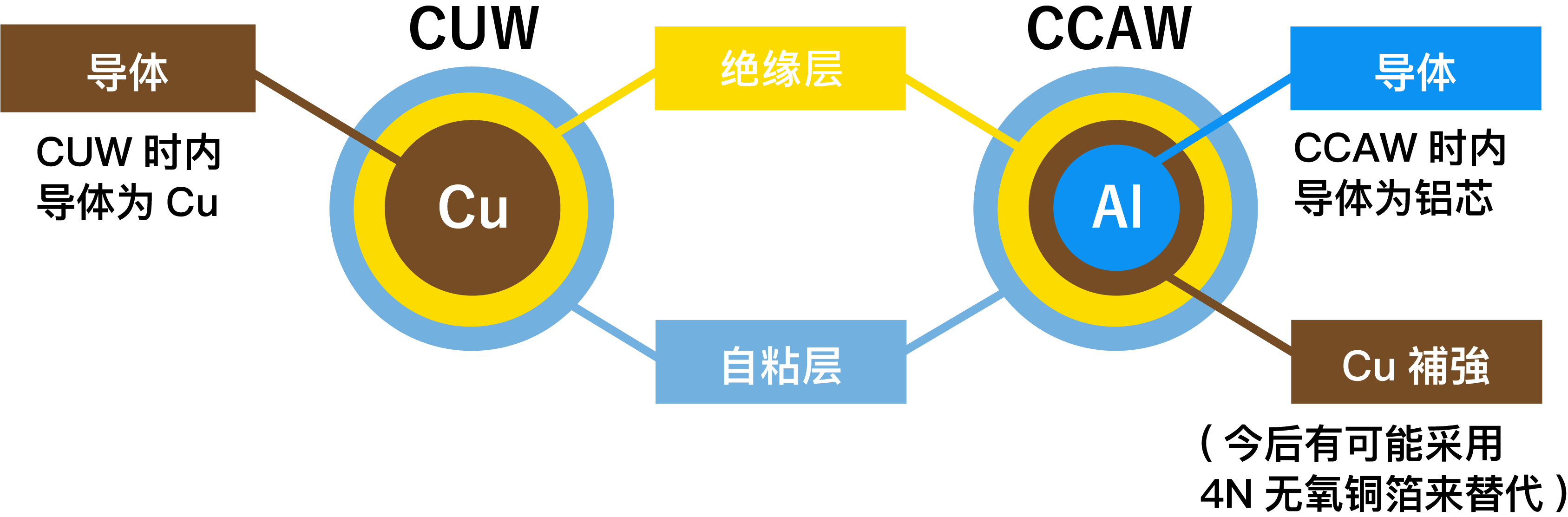

<漆包线的构造:>

2.骨架材料的特性

PENV(O)W漆包线、等同于其它电线生产商生产的SV漆包线、耐温等级155℃,对尼开製0.18与它社生产的0.18进行对应的性能测试,详见性能測試表A-1.

NH(EN)RA(O)W漆包线是尼开電機株式会社

独自开发的一款超高耐温等级的漆包线,耐温等级

210℃(UL規格相当),介于EI和AI之间。 绝缘漆EN胶水、配自粘漆RA胶水(比NV胶水有更高耐温等级的自粘漆),在国内处于领先的地位。目前国内的特种漆包线只是对绝缘漆的耐温等级进行了提高,而很少同时提高自粘漆的耐温等级。尼开電機株式会社生产的NH(EN)RA(O)W漆包线、不仅提高了绝缘漆的耐温等级、同时也提高了自粘漆的耐温等级。

尼开製NH(EN)RA(O)W0.30与它社生产的EI和AI自粘0.30漆包线进行对应的性能測定、详見性能測試 表A-2

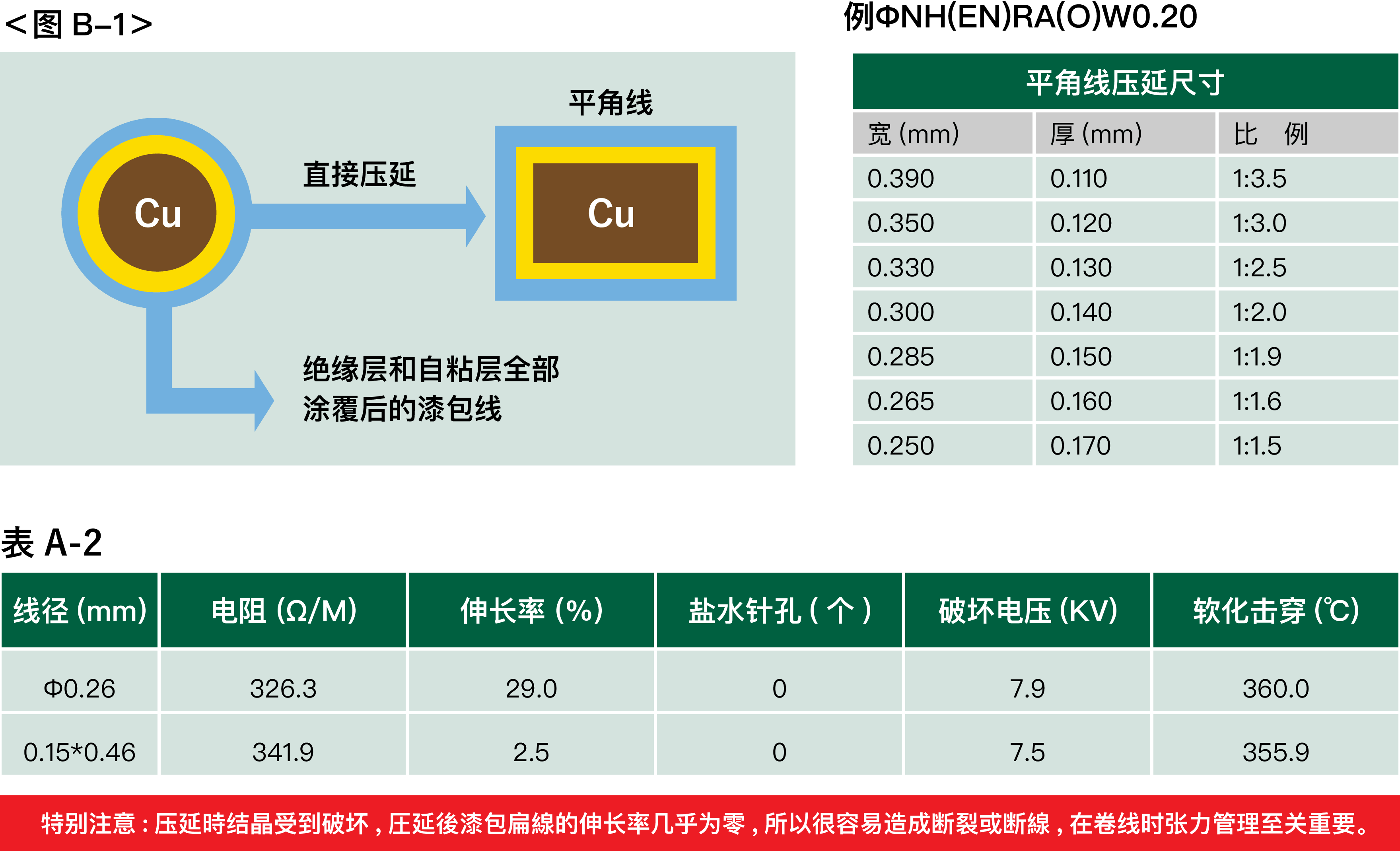

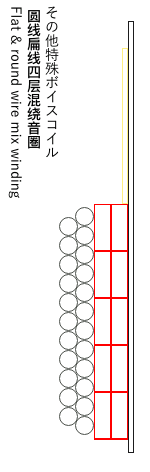

NH(EN)RA(O)W漆包线的皮膜具有较好的柔软性和延伸性,从而保证在压延过程中皮膜不开裂,可任意压延成所需的平角线或方线(见图B-1).

有关平角线的其它生产方式(见图B-2)

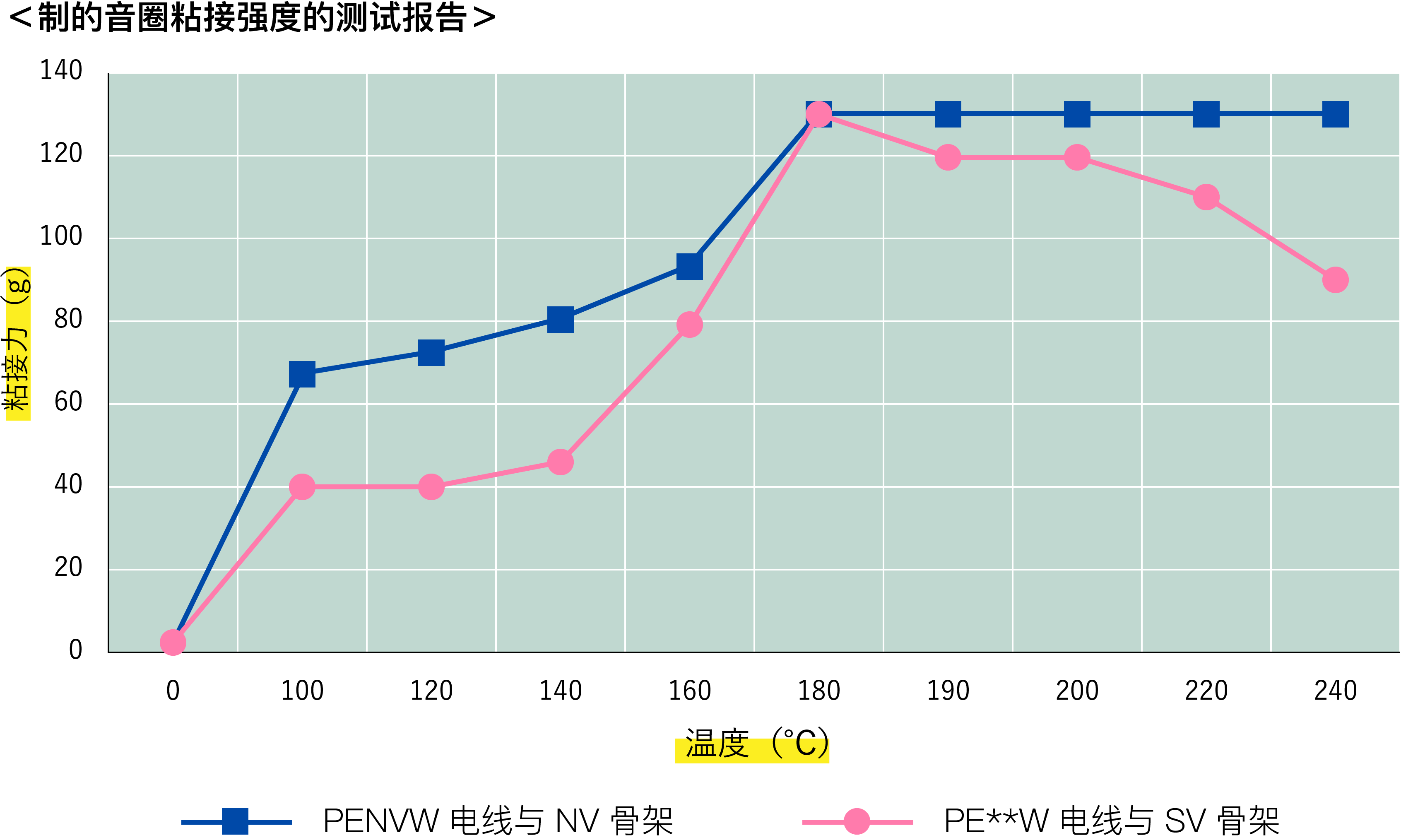

尼开製的PENVW漆包线和NV骨架绕制的音圈,与其它生产商生产的PE**W漆包线和SV骨架绕

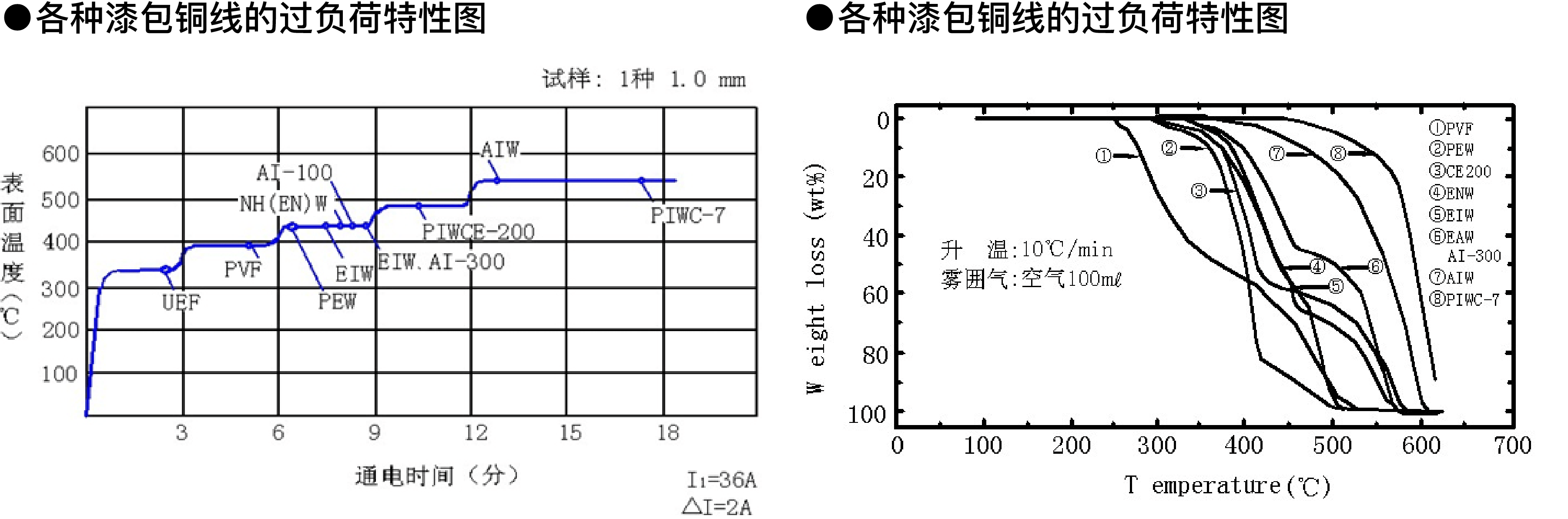

四、耐热性电线用的EN胶水的特性

特点:

1.与H级相当的耐热性绝缘材料;

2.与浸渍漆具有良好的兼容性;

3.最大的特点是有非常良好的皮膜剥离性;

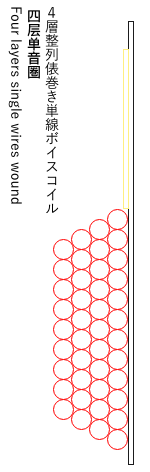

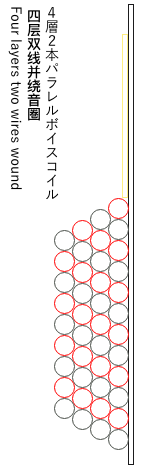

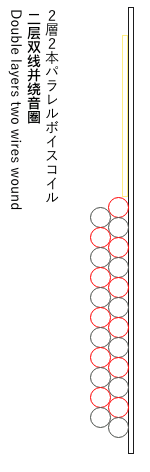

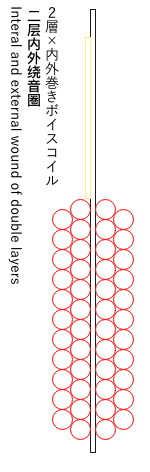

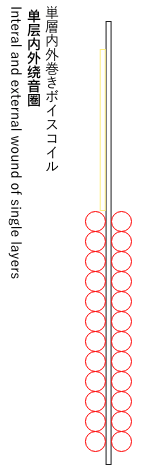

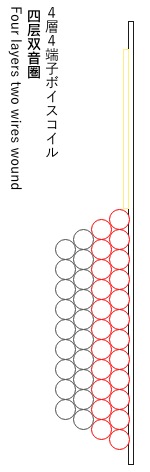

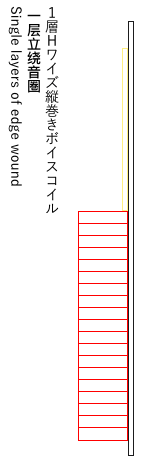

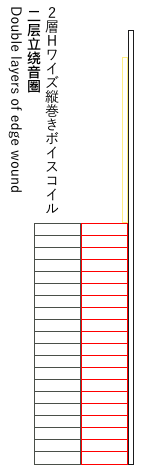

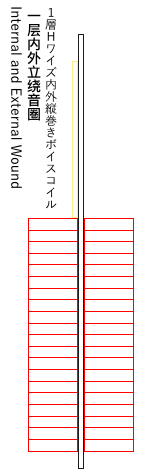

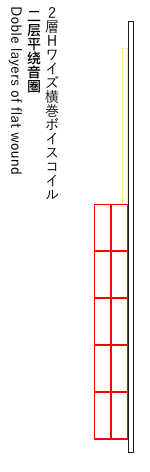

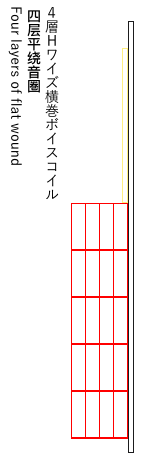

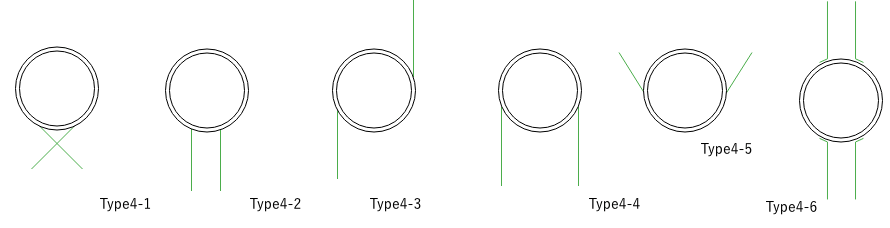

绕线方式

-

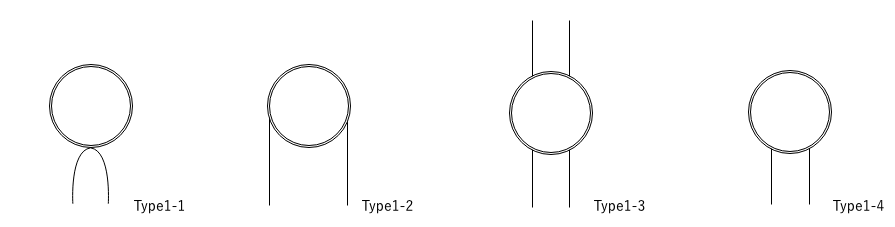

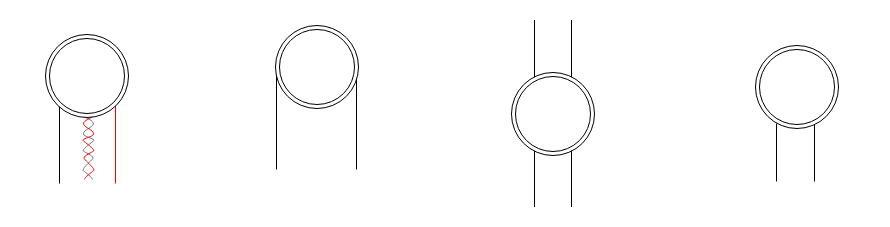

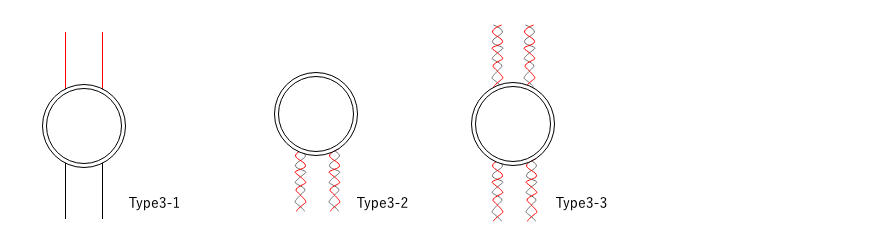

Type-1

-

Type-2

-

Type-3

-

Type-4

-

Type-5

-

Type-6

-

Type-7

-

Type-8

-

Type-9

-

Type-10

-

Type-11

-

Type-12

出线方式

-

二层音圏出线方式

-

四层音圏出线方式

-

双音圏出线方式

-

焊編织线音圏出线方式

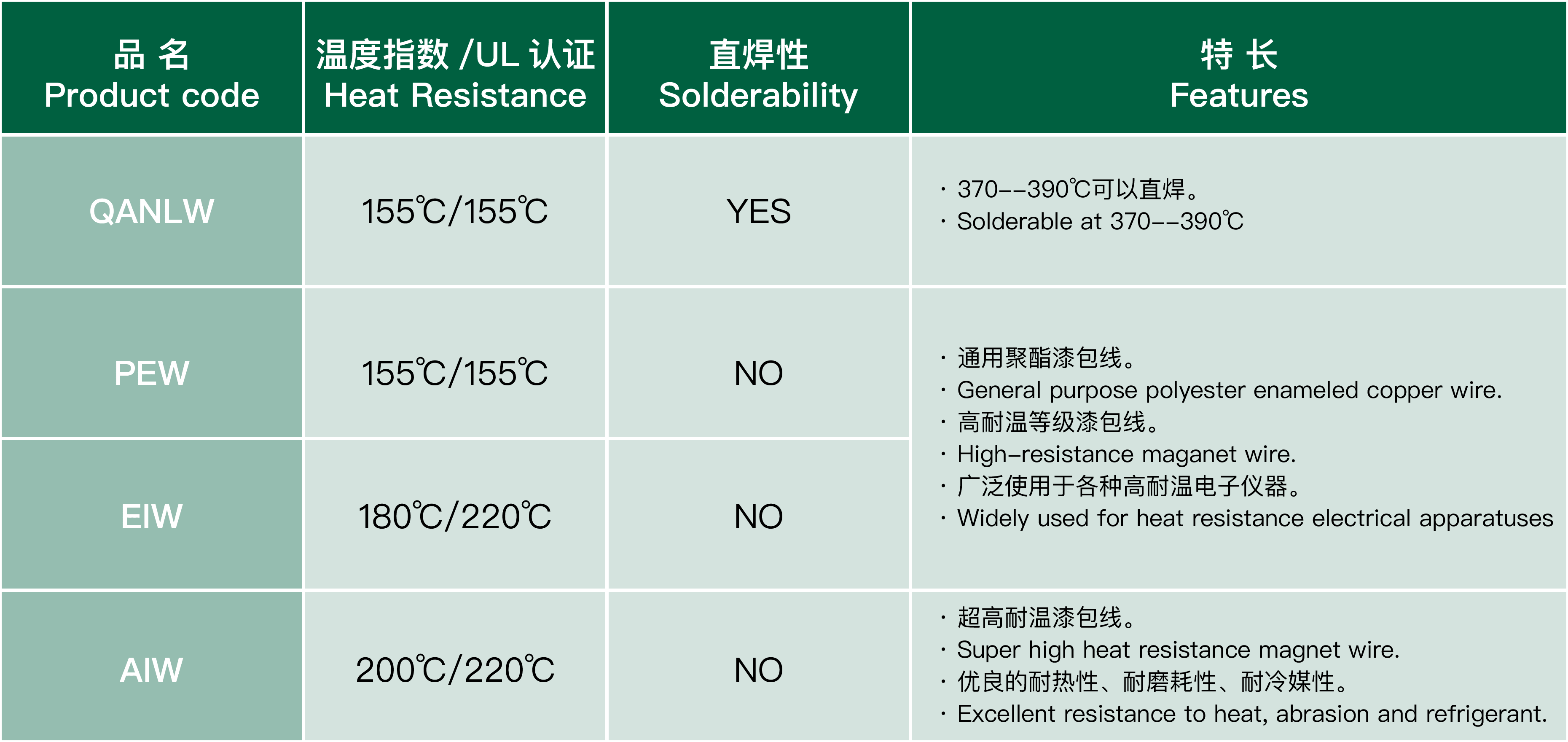

一. 普通漆包线General Magnet Wires

- 1. PEW 聚酯漆包线 Polyester enameled copper wire

- 2. EIW 聚酯亚胺漆包线 Polyester-imide enameled copper wire

- 3. AIW 聚酰氨酰亚胺漆包线 Polyamide-imide enameled copper wire

- 4. 普通漆包线对比表 Comparative table-General Magnet Wire

二. 自粘漆包线Self-Bonding Magnet Wires

- 1. NVW、RAW 热硬化型 Thermosetting type

- 2. LOCK 溶剂自粘 Solvent type

- 3. LOCK Y1自滑性热风自粘 Smooth surface ,hot air type

- 4. LOCK Y3自滑性高温热风、通电自粘 Smooth surface,high temperature hot air,electric current type

- 5. LOCK Y5自滑性高温热风、通电自粘 Smooth surface,high temperature hot air,electric current type

- 6. LOCK Y7自滑性高温热风、通电自粘 Smooth surface,high temperature hot air,electric current type

- 7. LOCK Y9自滑性高温热风、通电自粘 Smooth surface,high temperature hot air,electric current type

- 8. 自粘漆包线特性对比表 Comparative table self-bonding magnet wires

三. 特殊漆包线Special Magnet Wires

- 1. HT20W 高张力线 High tension magnet wire

- 2. HT40W 超高张力 Super high tension magnet wire

- 3. CCAW 铜包铝漆包线 Copper-clad aluminum wire

普通漆包线 General Magnet Wires

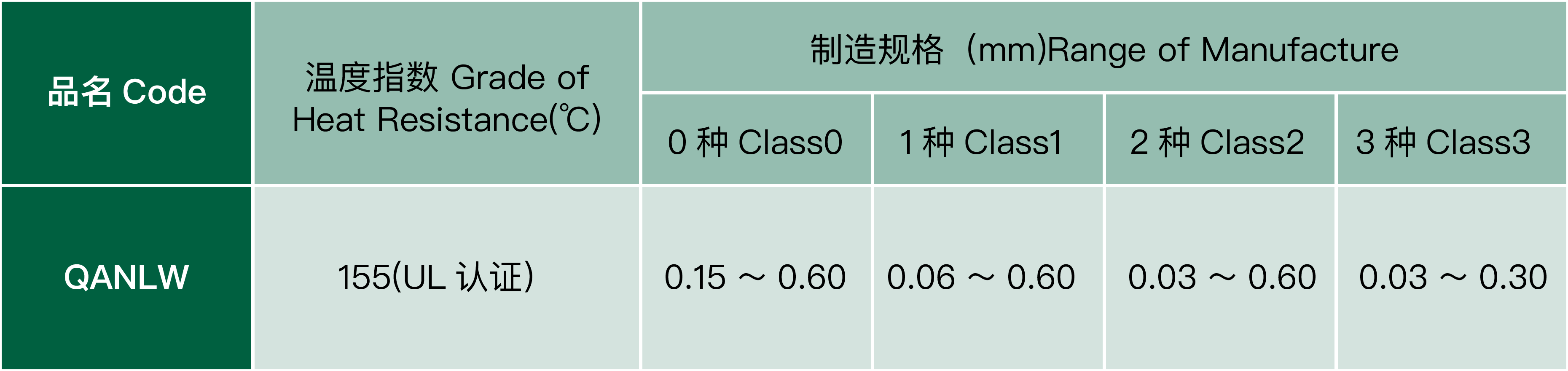

QANLW 直焊性漆包线Solderable Enameled Copper Wire

● 特长 Features

- ① 耐热性介于聚氨酯和聚酯之间; Heat resistance between polyurethan and polyester;

- ② 380度可直焊; Solderable at 380℃

- ③ 可以着色 Colorable

- ① 适用标准: JCS 394 “可直焊漆包线”;Applicable standards:JCS 394 Solderable enameled round copper winding wires

- ② 用 途 : 小型马达 、各种小型变压器、继电器线圈。Applications: small motors,small transformers for electronic equipment,relay coils.

- ③ 温度指数及制造范围

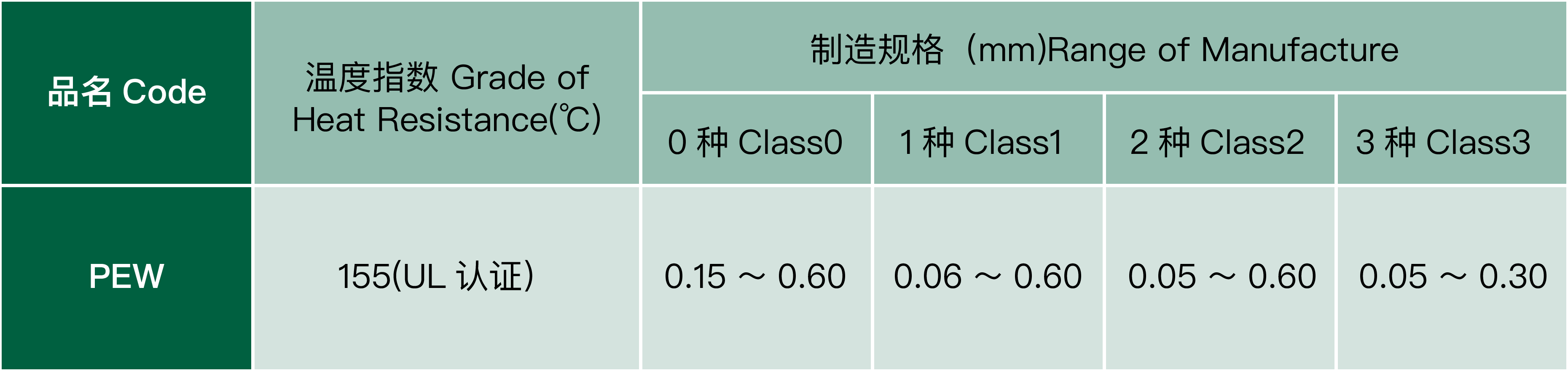

PEW 聚酯漆包线Polyster Enameled Copper Wire

● 特长 Features

- ① 耐溶剂性优良; copper winding wires";Excellent resistance to solvents.

- ② 耐水解性不好,在密闭装置使用需注意; Low resistance to ydrolysis. Care should be taken when applying to

- ① 适用标准: JIS C 3202 “聚酯漆包圆铜线”; Applicable atandards:JIS C3202 "Polyester enameled round

- ② 用途:通用马达、便携式发电机、变压器、螺线管、继电器; Applications: General purpose motors,protable generators,transformers, solenoid, relay coils.

- ③ 温度指数及制造范围

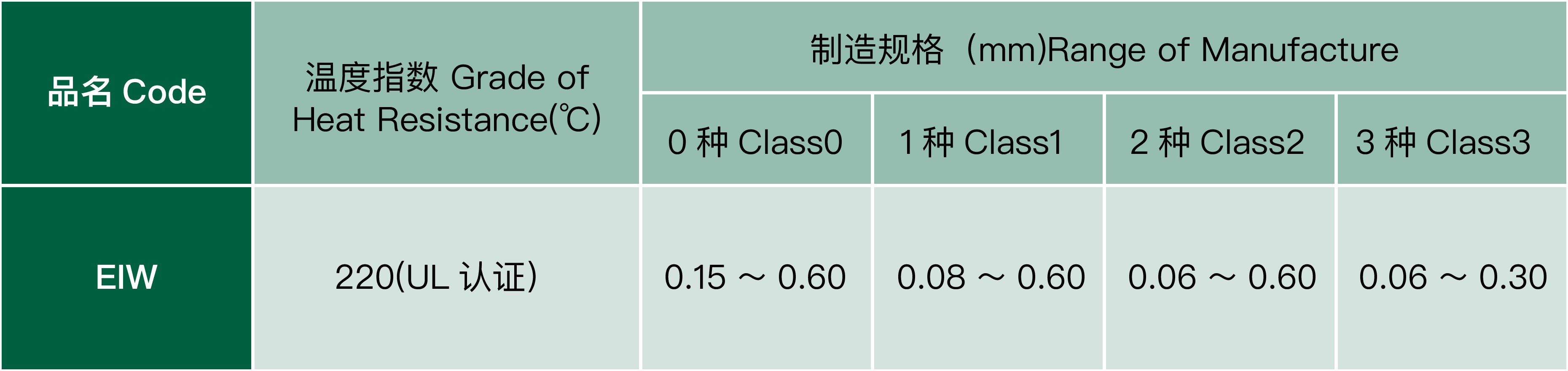

EIW 聚酯亚胺漆包线Polyester-imide Enameled Copper Wire

● 特长 Features

- ① 优良的电气、化学、机械性能; Excellent electrical,chemical and me-chanical properties;

- ② 温度指数180度,广泛使用于热要求较高的电子元件中; Heat resistant up to 180℃, Widely used for electrical apparatuses which requires heat resistance;

- ③ 可能有龟裂现象发生。 May develop crazing.

- ① 适用标准:JIS C3202"聚酯亚胺漆包圆铜线"; Applicable standards:JIS C3202"Polyesterimide enameled round copper winding wires".

- ② 用途:耐热冲通用马达、变压器、汽车配件; Applications: Heat-resistant general-purpose motors,transformers,automotive parts.

- ③ 温度指数及制造范围

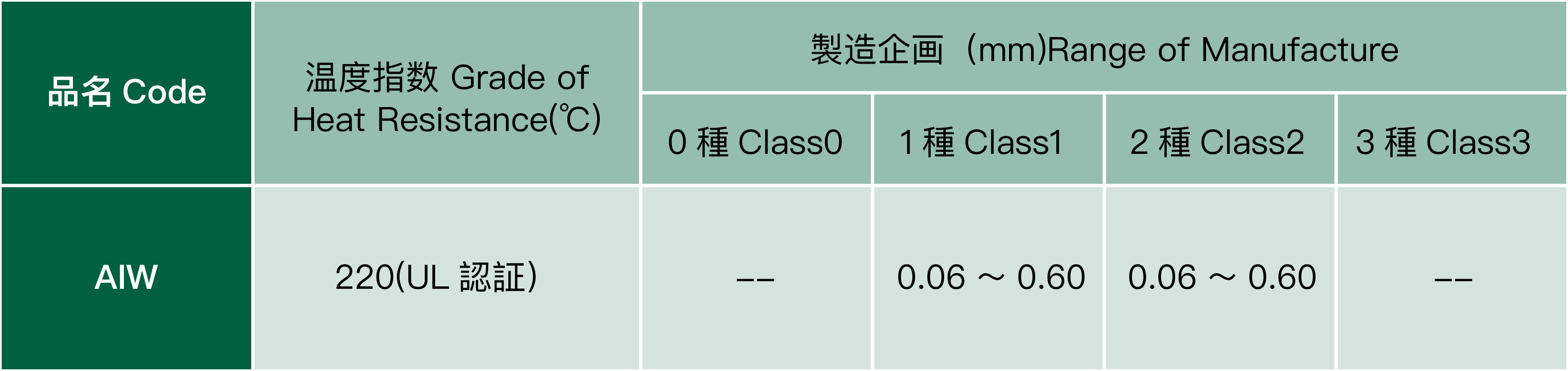

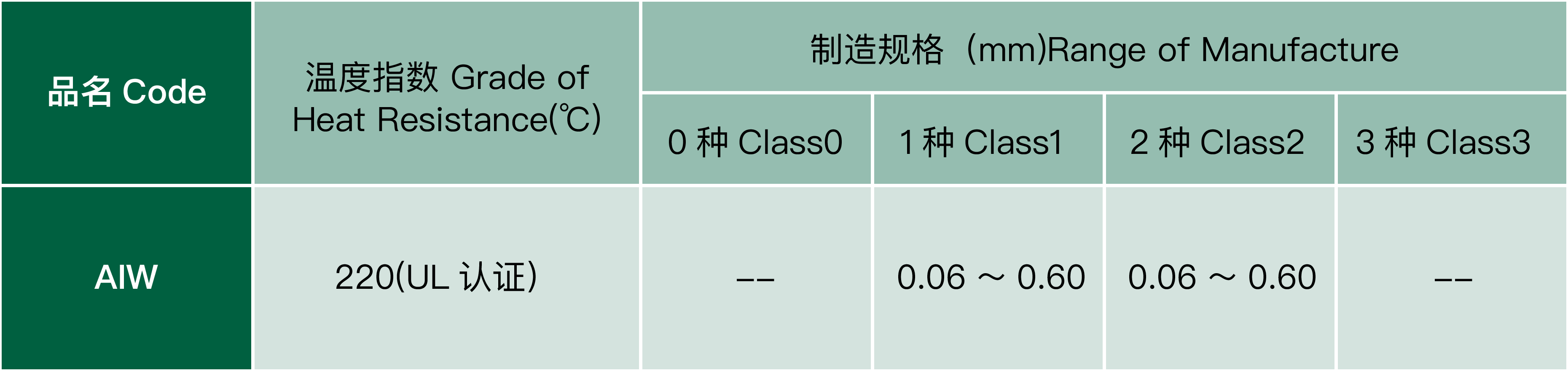

AIW 聚酰氨酰亚胺漆包线Polyamide-imide Enameled Copper Wire

● 特长 Features

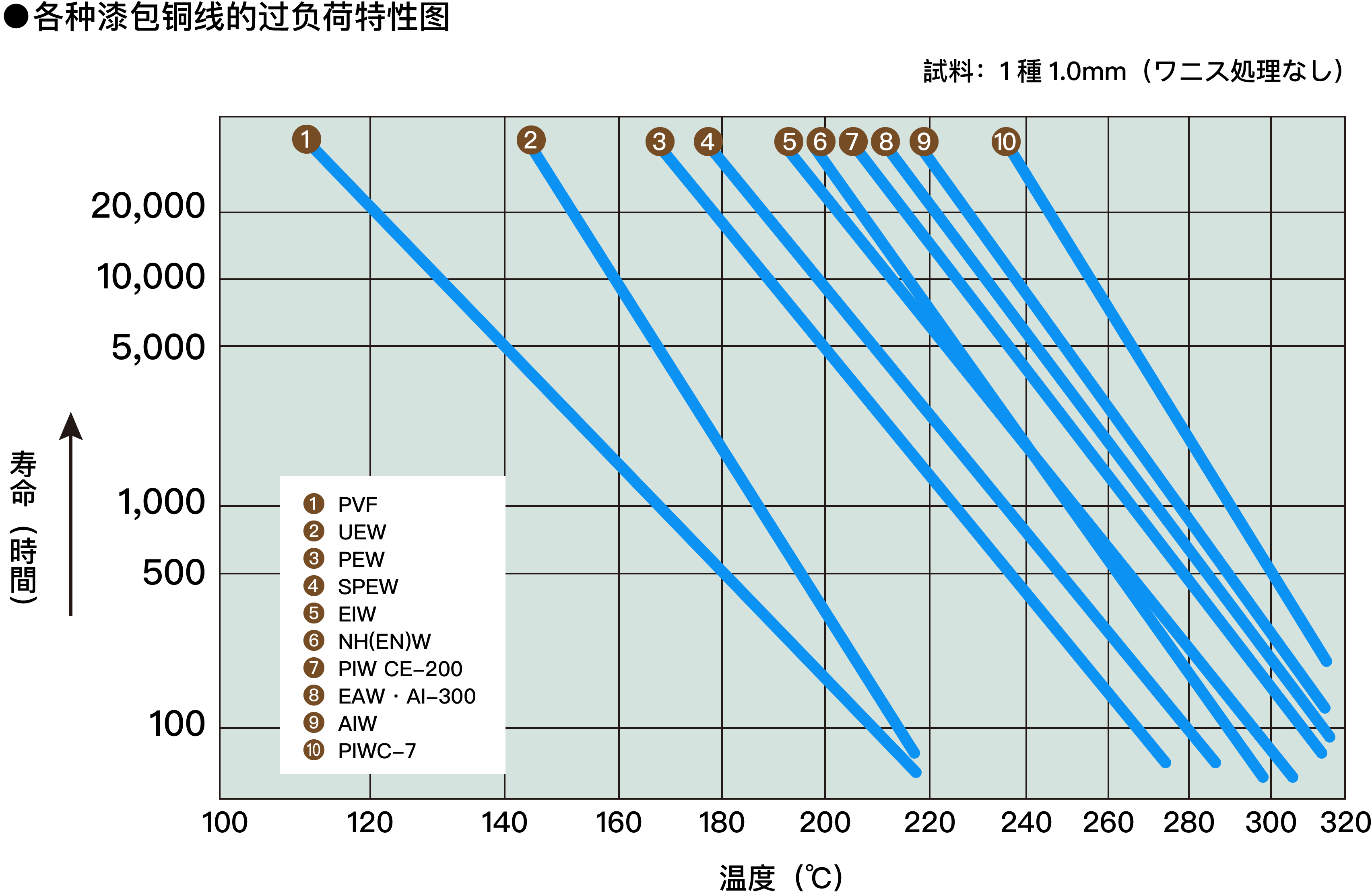

- ① 比EIW有更优良耐热、耐磨耗、耐冷媒性; Higher resistance to heat,abr-asion and refrigerants than those of EIW wire.

- ② 温度指数200度,耐过载优异,适合各类需耐高热性的电子原器件中。 With heat resistance up to 200℃ a-nd high resistance to overload, the wire can be safely used for electrical apparatus which is requires heat-resistance.

- ① 适用标准:JCS 334"聚酰氨酰亚胺漆包圆铜线"; Applicable standards:JCS 334"polyamideimide enamelad round copper winding wires".

- ② 用途:高耐温马达、电动工具、耐高温干式变压器、电磁阀; Applications: Heat-resistance motors, motors for electric tools,heat-resistance dry type transformers, lifting magnet coils.

- ③温度指数及制造范围

一般磁力线对比图

Comparative Table - General Magnet Wires

普通漆包线对比表 Comparative Table - General Magnet Wires

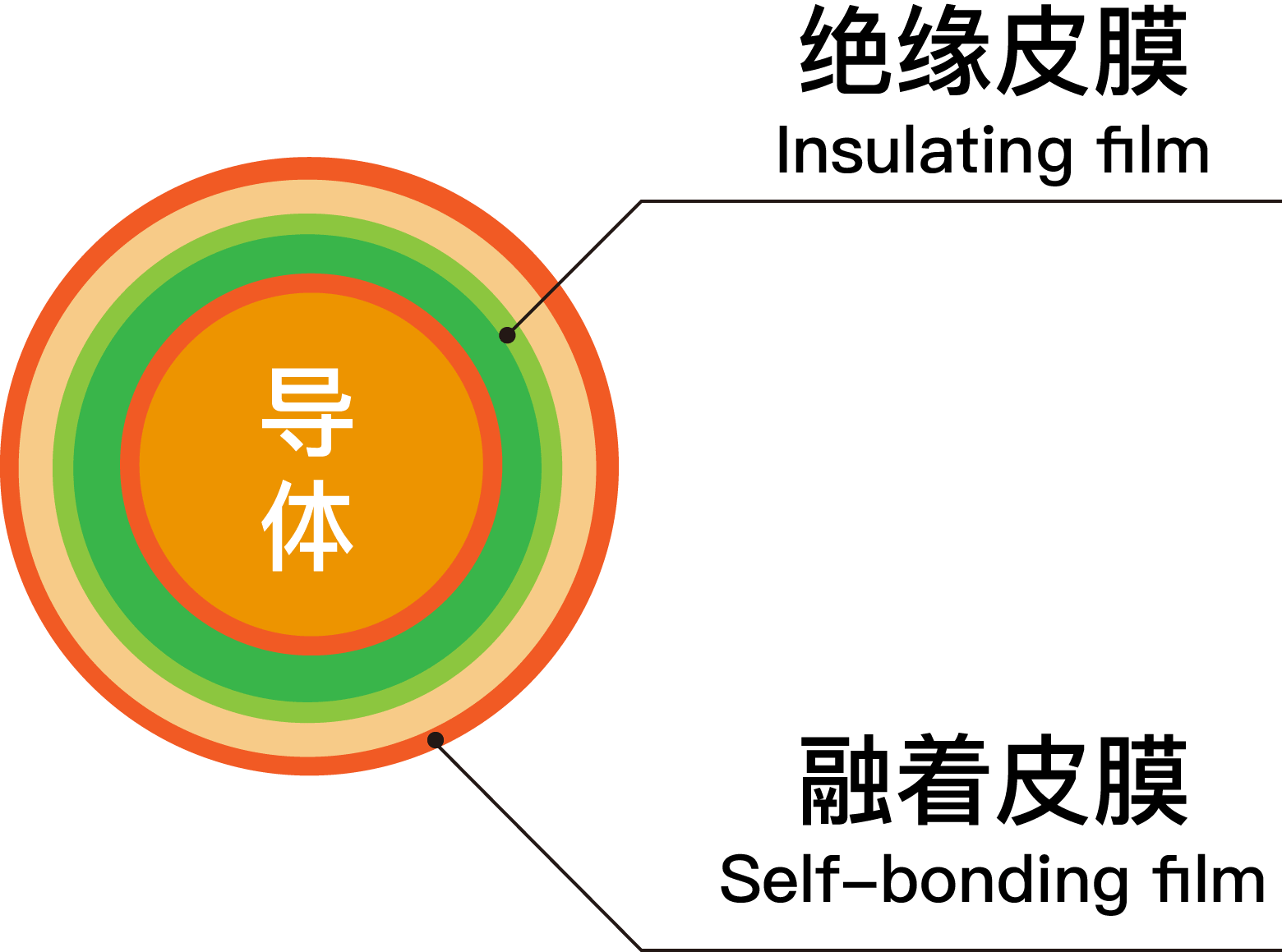

构造Structure

自粘漆包线是双层漆包线,是在绝缘层的的外层再涂上一层具有热塑性、热硬化绝缘皮膜型或者其它材质的自粘涂层,绝缘层皮膜一般为聚氨酯、聚酯或其它类似的材料我公司生产各种自粘层和绝缘层组合的适合客户不同需求的自粘漆包线。

The self-bonding magnet wire is a double layered copper conductor covered with a layer of self-bonding film auch as thermoplastic resin or other materical over a layerof insulating film such as polyurethane,polyeater or similar material.

We manufacture a wide variety of self-bonding wires by expertly combining the bonding layer with the insulating film to meet customers' need.

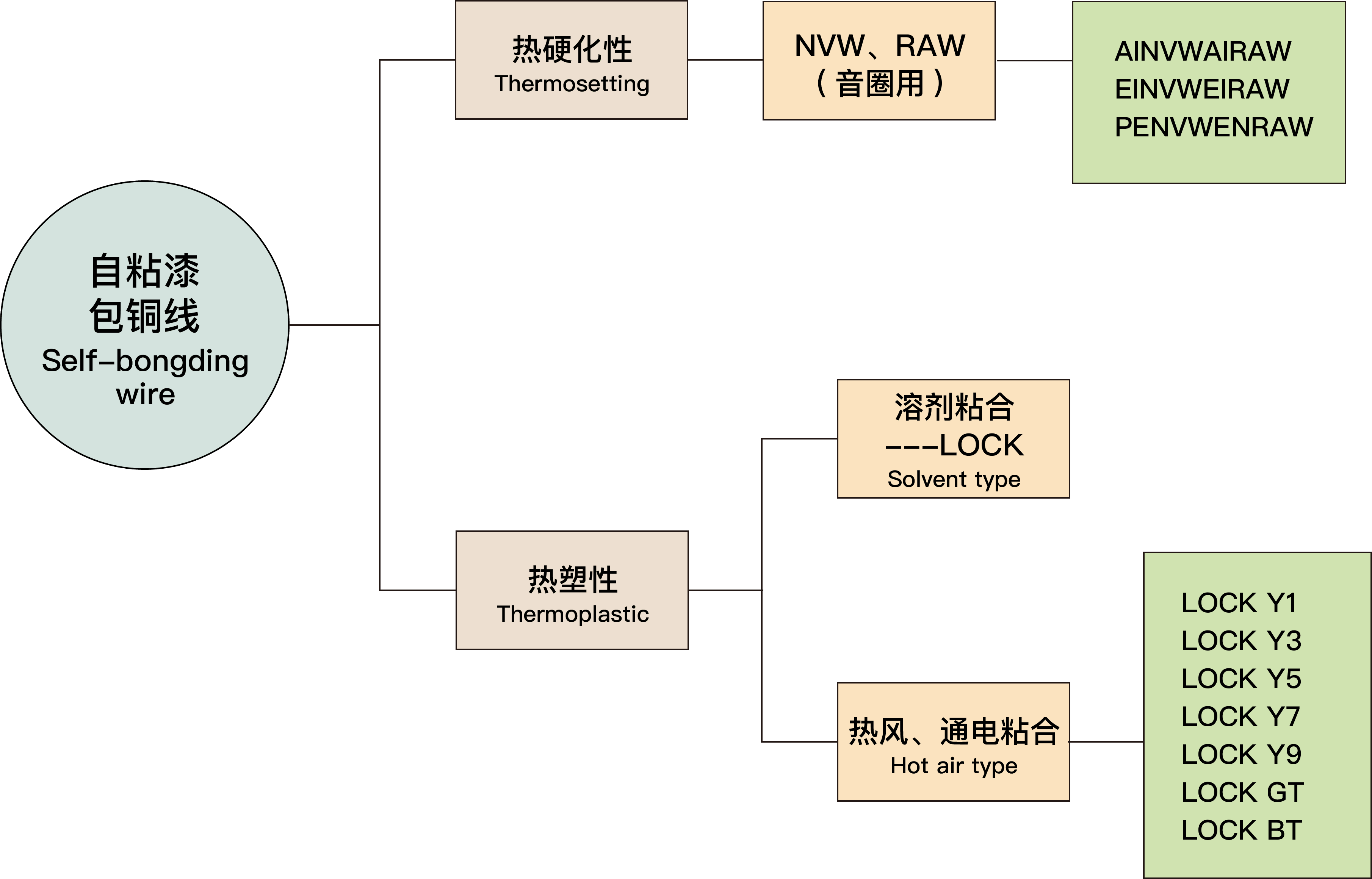

分类Classification of bonding layers

※热硬化型在卷成线圈后加热处理,使得热硬化性皮膜变成三维空间的热稳定性结构。

After winding, the coil heated to change its thermosetting film into a thermally stable three-dimensional structure.

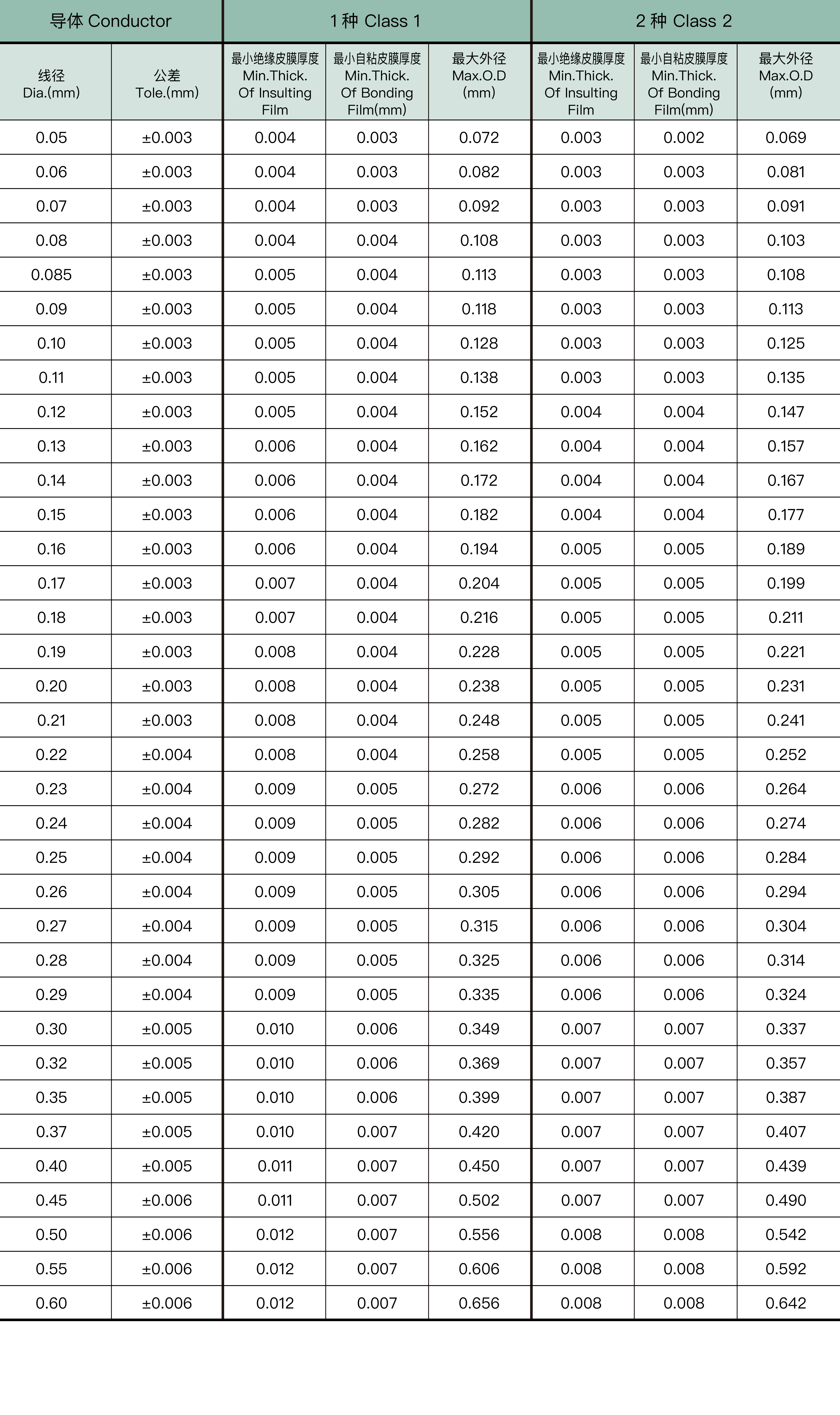

热硬化型自粘漆包线寸法表(NVW、RAW)Size of Thermelsetting Self-Bonding Magnet Wires(NVW、RAW)