Bobbin

Bobbin

Bobbin

Bobbin

Names of bobbin materials (product numbers)

and their characteristics

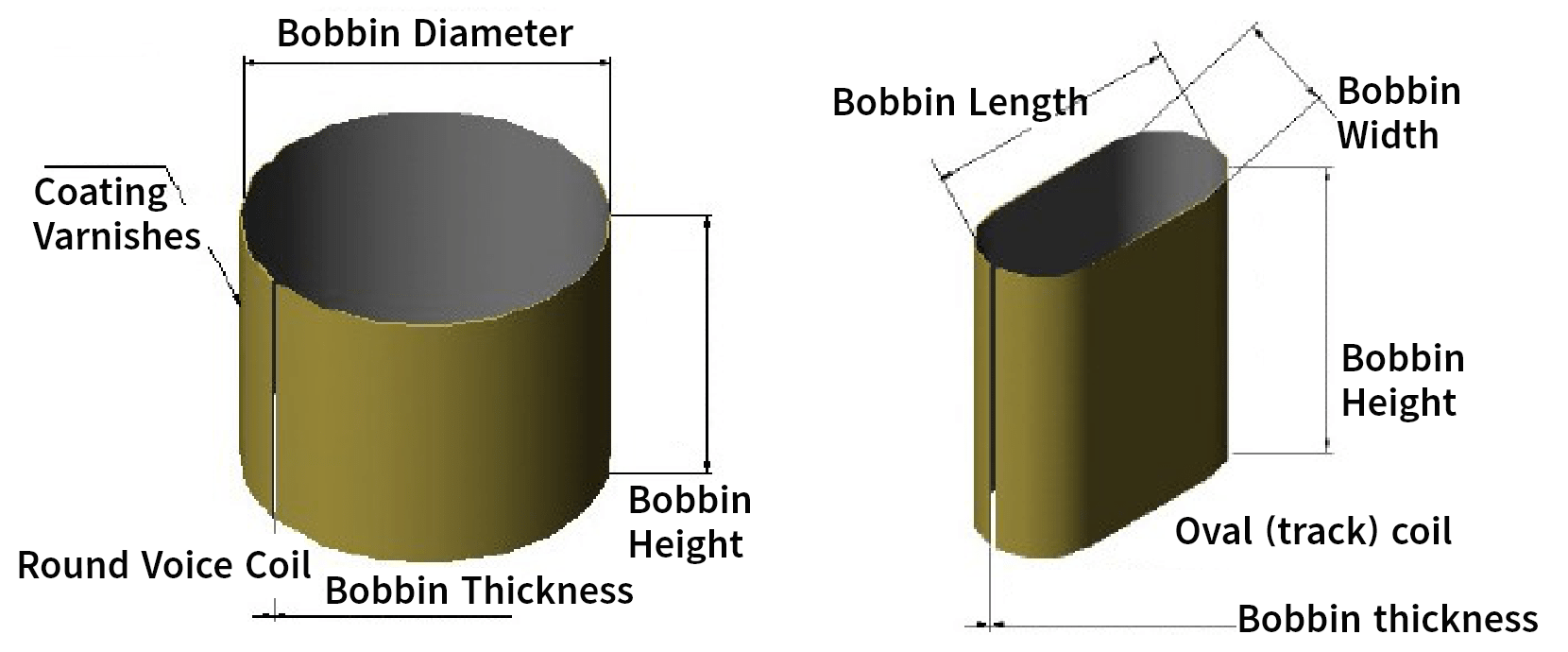

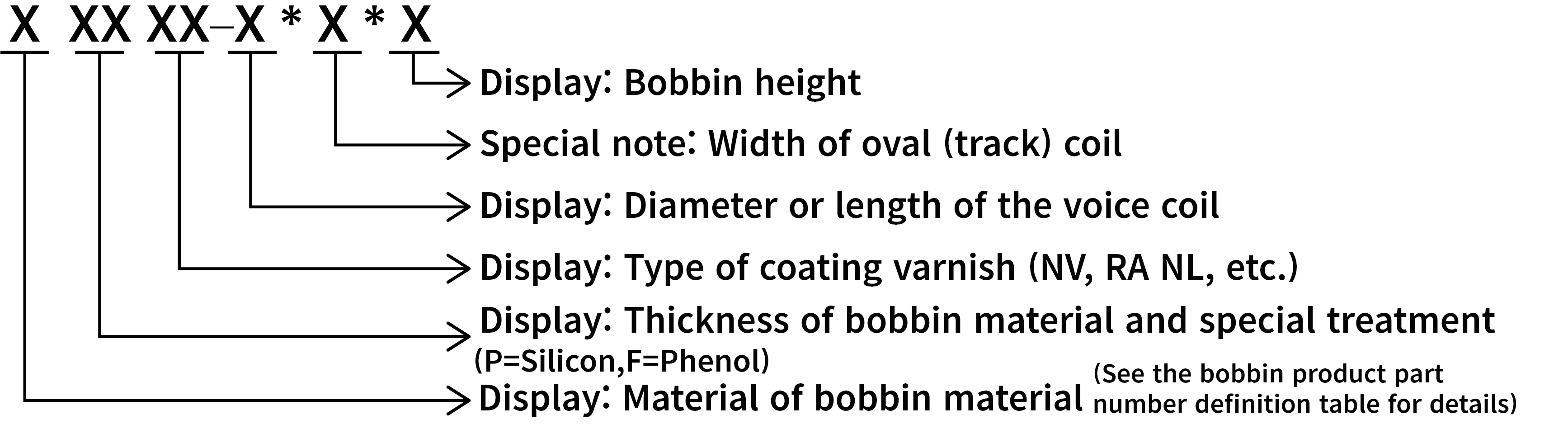

Standard: Method of describing the product name

(product part number) of bobbin materials

<Coating structure of bobbin material>

●Description of bobbin material type and coating method

| Material Name | Material code number | Varnish coating method | ||

|---|---|---|---|---|

| Bobbins for round voice coils | Bobbins for oval (track) coils | H Bobbin for wise | ||

| aluminum foil | A | Hz isolation +S Processing | Hz isolation + Secondary processing | Hz isolation +H Processing |

| Polyimide film(Kapton) | C | S Processing | Secondary processing | H Processing |

| Meta-aramid fibers (Nomex) |

N | S Processing | Secondary processing | H Processing |

| Paper | K | S Processing | Secondary processing | H Processing |

| Phenol impregnation Glass fiber(TIL) |

T | S Processing | Secondary processing | H Processing |

| Copper foil | B | S Processing |  |

|

| Titanium Foil | Ti | Hz isolation +S Processing | Elliptical shape(truck) Bobbins for coils |

|

| Vertical paper with silicone | K(+P) | S Processing | Secondary processing |  |

| Stiffening paper | KL | S Processing |  |

|

| Fairy Flower Paper | S Processing |  |

|

|

| Polyimide film (Kapton)Stiffening paper |

CL | S Processing |  |

|

※Hz=Insulation code indication(Coating thickness 10μm以上)

※H=H treatment method for coating thickness 6μm以上

※S=S treatment method for coating thickness 6μm以上

Properties of bobbin materials

NV bobbins and SV bobbins are equivalent products, and are effective when used in combination with PENVW wires

By using a combination of RA bobbin material and NH (EN) RAW wire, the synergistic effect of heat resistance will maximize temperature resistance and adhesive strength

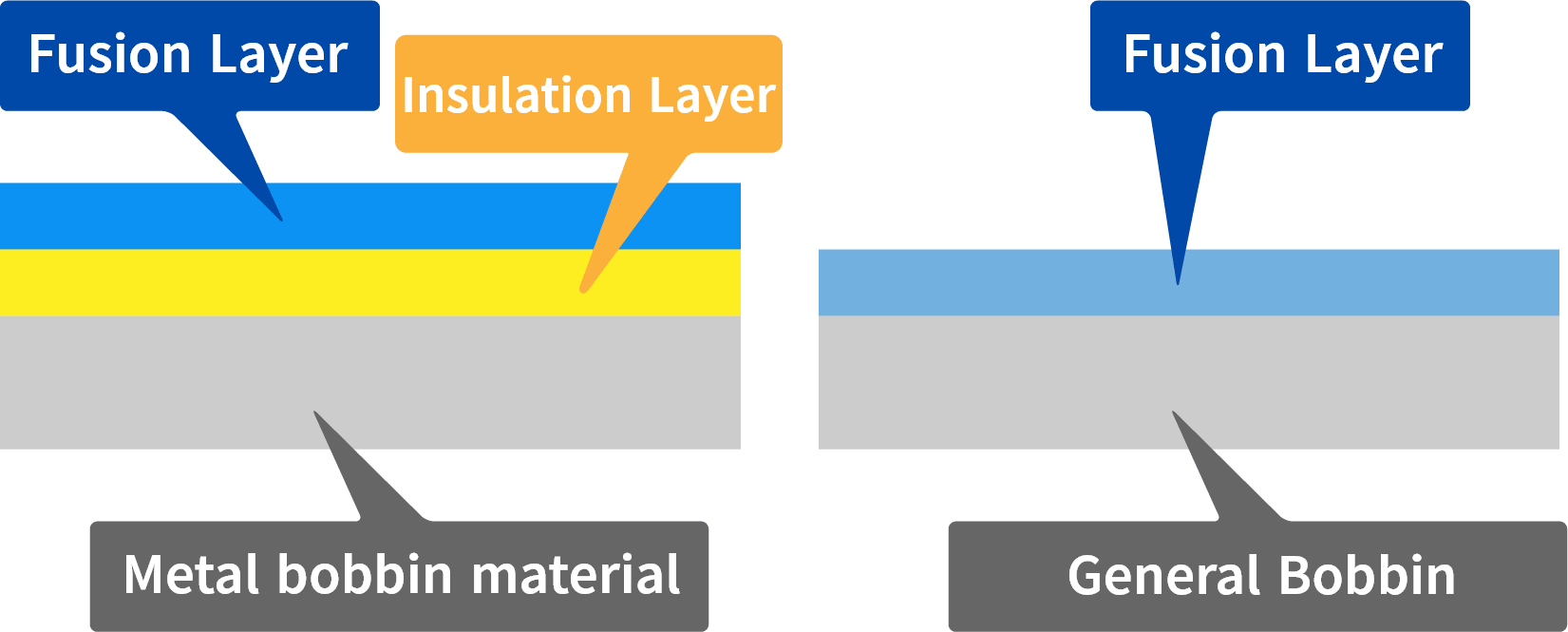

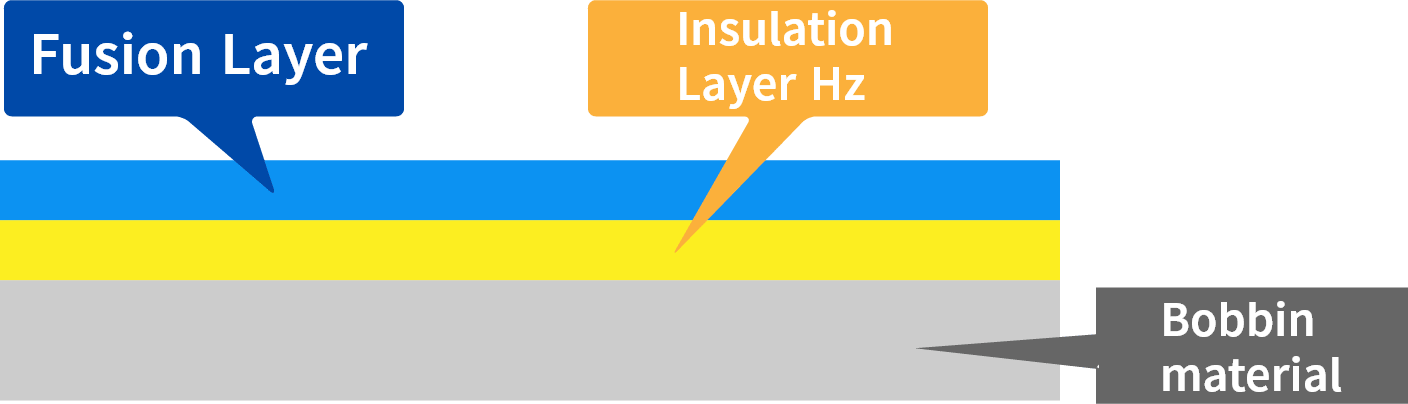

<Coating structure of bobbin material>

Features

Hz+S treatment method is used to create an insulating layer on the metal bobbin material, which prevents short-circuiting of both the metal bobbin material and the magnet wire

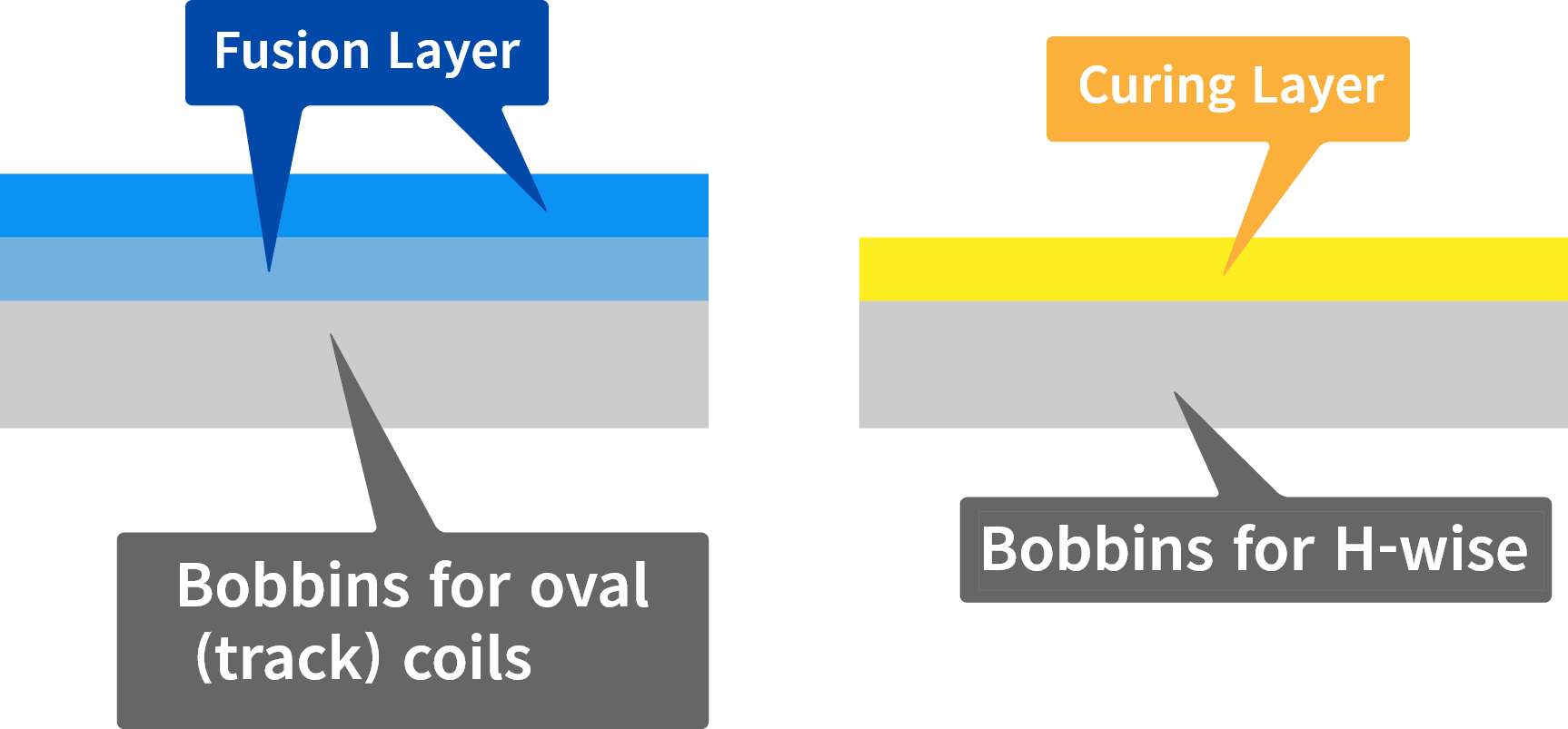

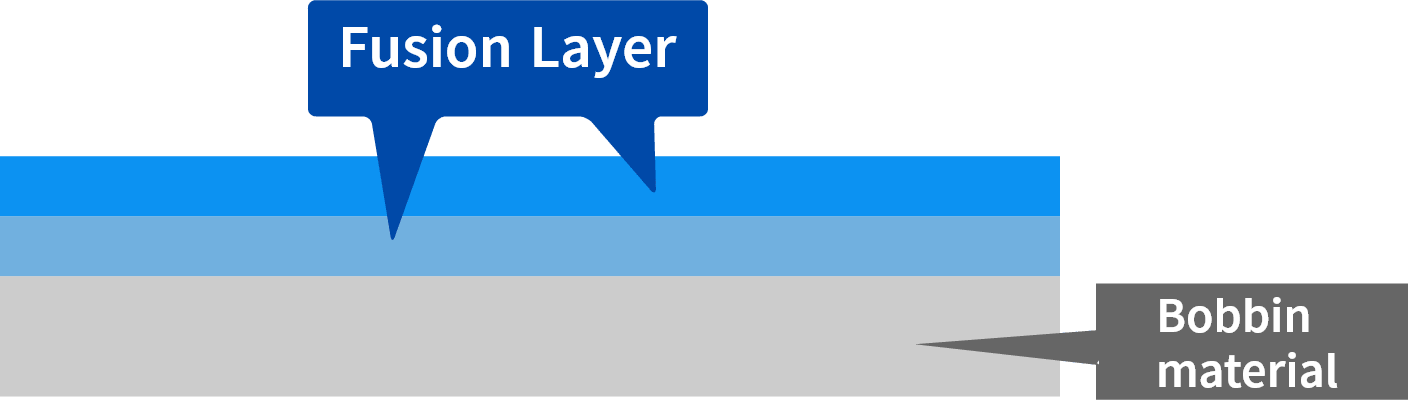

<Coating structure of bobbin material>

Features

S+S processing method is used to increase the strength of the flat part of the elliptical (track) coil and the R-curved surface, which improves the adhesive strength and prevents poor adhesion and dropping of the bobbin and magnet wire

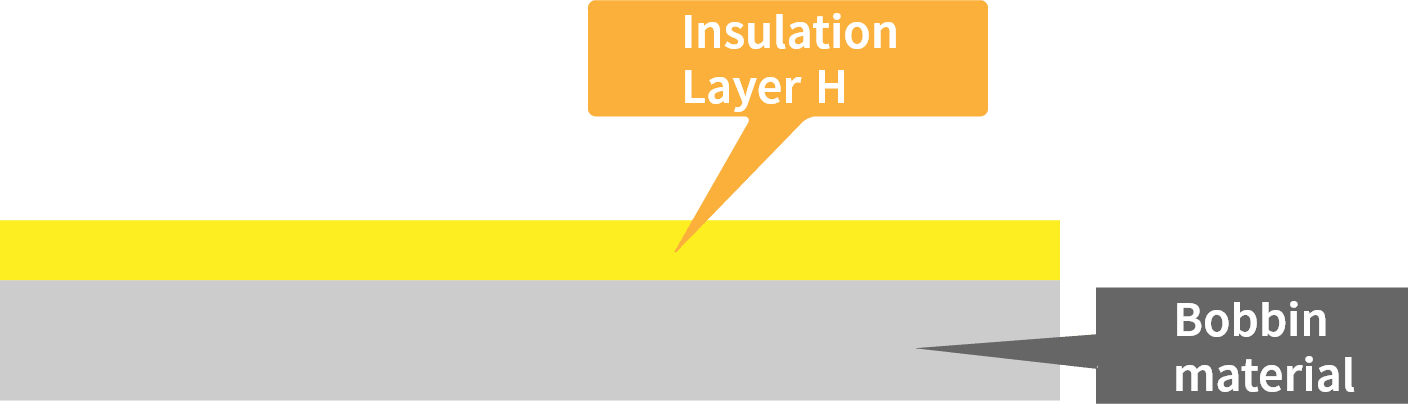

<Coating structure of bobbin material>

Features

The special treatment method of H is used for H-wise voice coil. It avoids winding defects in the wire alignment that occur with horizontal or vertical winding

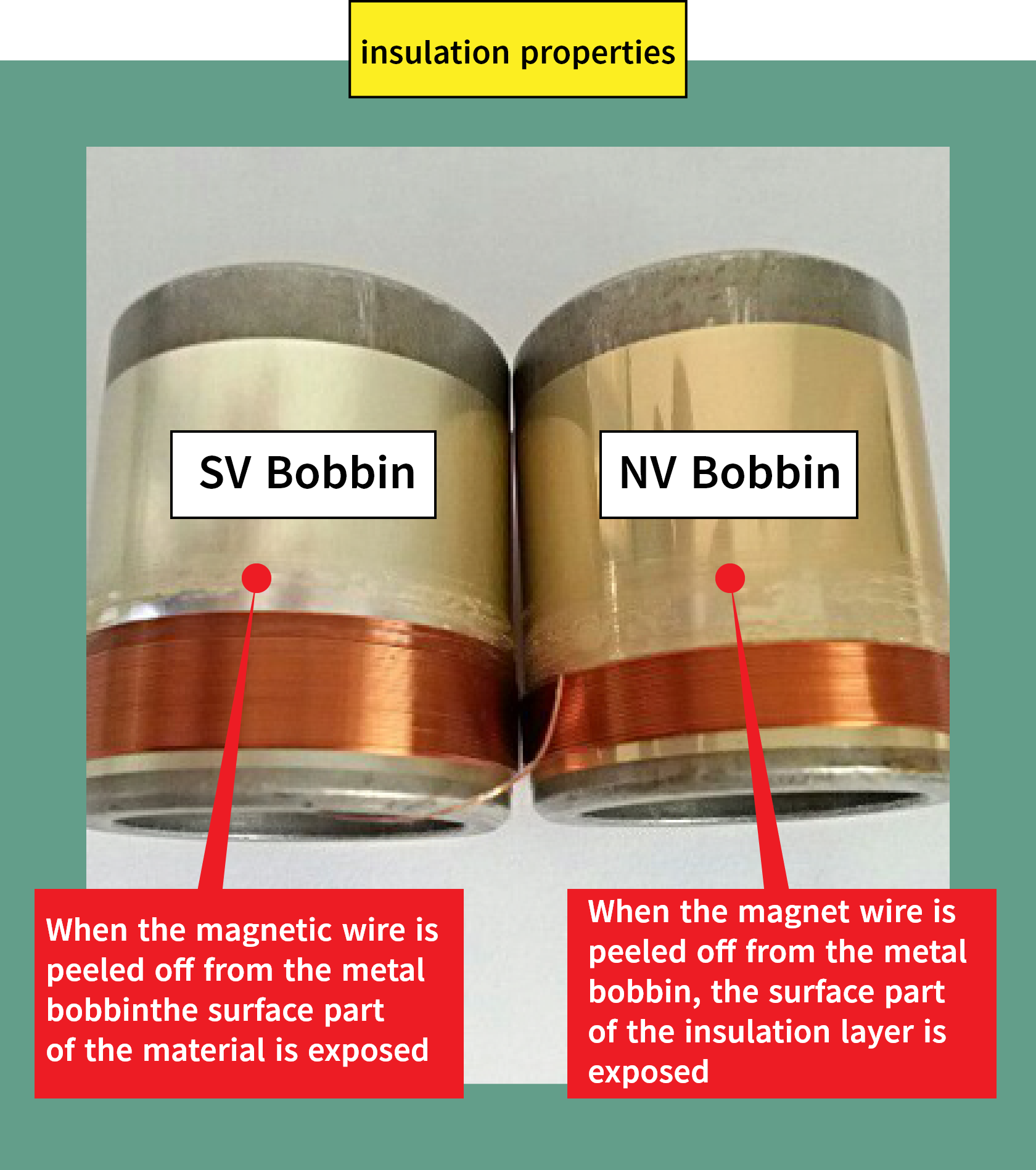

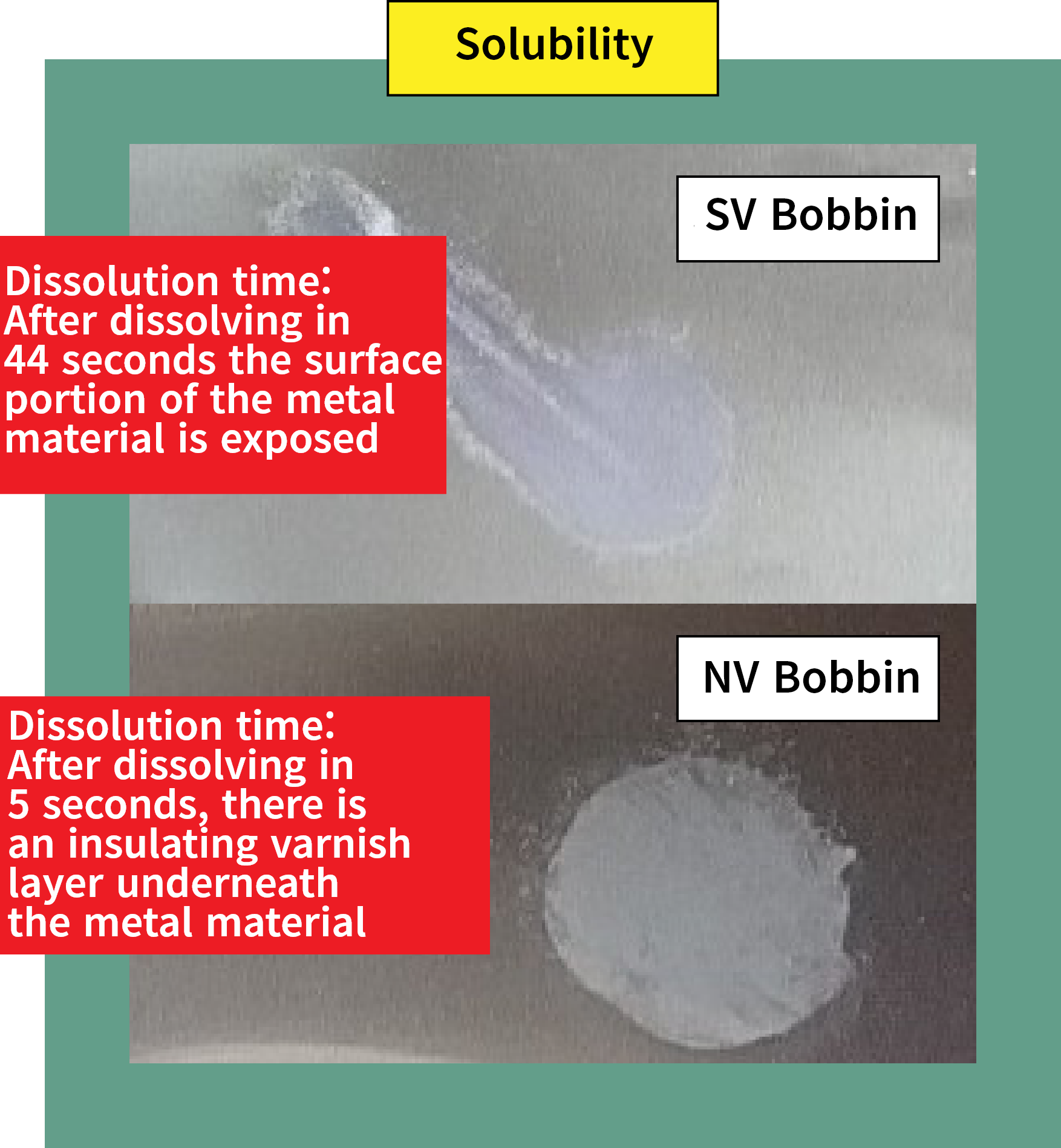

Conducted comparative testing of insulation and solubility between Nikkay's NV metal bobbins and SV metal bobbins produced by other manufacturers

Nikkei's bobbins have an insulating layer on the metal material, and the insulating layer remains even after dissolution experiments with alcohol

Bobbin Material Lineup

Bobbin Specification

| Raw Materials | Thickness | Varnish paint | Name | Heat resistance(℃) | Bonding Wire |

|---|---|---|---|---|---|

| KRAFT PAPER | 0.05m/m 0.08m/m 0.10m/m 0.13m/m |

JYB-B2 | KL | 150℃MAX | LOCK WIRE |

| NV | KNV | 180℃MAX | PENV WIRE | ||

| RA | KRA | 210℃MAX | NH(EN)RA WIRE | ||

| ALUMINUM | 0.03m/m 0.05m/m 0.08m/m 0.10m/m 0.12m/m 0.15m/m 0.20m/m |

JYB-B2 | AL | 150℃MAX | LOCK WIRE |

| NV | ANV | 200℃~220℃ AVERAGE | PENV WIRE | ||

| 250℃MAX | |||||

| RA | ARA | 230℃~250℃ AVERAGE | NH(EN)RA WIRE | ||

| 280℃MAX | |||||

| ANODIZED ALUMINUM (BLACK) |

0.08m/m 0.10m/m 0.12m/m 0.15m/m 0.20m/m |

NV | AONV | 200℃~220℃AVERAGE 250℃MAX | PENV WIRE |

| RA | AORA | 230℃~250℃AVERAGE 280℃MAX | NH(EN)RA WIRE | ||

| NOMEX | 0.05m/m 0.08m/m 0.13m/m |

JYB-B2 | NL | 200℃MAX | LOCK WIRE |

| NV | NNV | 180℃~200℃ AVERAGE | PENV WIRE | ||

| 220℃ MAX | |||||

| RA | NRA | 210℃~230℃ AVERAGE | NH(EN)RA WIRE | ||

| 250℃MAX | |||||

| BRASS | 0.03m/m 0.05m/m 0.08m/m 0.10m/m |

NV | CUNV | 200℃~220℃ AVERAGE | PENV WIRE |

| 250℃MAX | |||||

| RA | CURA | 230℃~250℃ AVERAGE | NH(EN)RA WIRE | ||

| 280℃MAX | |||||

| PI (KAPTON) |

0.03m/m 0.05m/m 0.08m/m 0.10m/m 0.125m/m 0.15m/m 0.20m/m |

NV | CNV | 200℃~220℃ AVERAGE | PENV WIRE |

| 250℃MAX | |||||

| RA | CRA | 230℃~250℃ AVERAGE | NH(EN)RA WIRE | ||

| 280℃MAX | |||||

| GLASS FIBER (TIL) |

0.08m/m 0.125m/m 0.15m/m 0.20m/m |

NV | TNV | 200℃~220℃ AVERAGE | PENV WIRE |

| 250℃MAX | |||||

| RA | TRA | 230℃~250℃ AVERAGE | NH(EN)RA WIRE | ||

| 280℃MAX | |||||

| KRAFT PAPER | 0.05m/m 0.08m/m 0.10m/m 0.13m/m |

JYB-B2 | KPL | 150℃MAX | LOCK WIRE |

| NV | KPNV | 180℃MAX | PENV WIRE | ||

| RA | KPRA | 210℃MAX | NH(EN) RA WIRE | ||

| TITANIUM FOIL | 0.05m/m 0.10m/m |

NV | TiNV | 200℃~220℃ AVERAGE | PENV WIRE |

| 250℃MAX | |||||

| RA | TiRA | 230℃~250℃ AVERAGE | NH(EN)RA WIRE | ||

| 280℃MAX | |||||

| PI (KAPTON) SILICON CONTAINING |

0.08m/m | NV | CPNV | 200℃~220℃ AVERAGE | PENV WIRE |

| 250℃MAX | |||||

| RA | CPRA | 230℃~250℃ AVERAGE | NH(EN)RA WIRE | ||

| 280℃MAX | |||||

| DURALUMIN | 0.05m/m 0.08m/m 0.13m/m |

JYB-B2 | DAL | 150℃MAX | LOCK WIRE |

| NV | DANV | 200℃~220℃ AVERAGE | PENV WIRE | ||

| 250℃MAX | |||||

| RA | DARA | 230℃~250℃ AVERAGE | NH(EN)RA WIRE | ||

| 280℃MAX |

REINFORCEMENT SPECIFICATION

| Raw Materials | Thickness | Coating Varnishes | Name | Heat resistance(℃) |

|---|---|---|---|---|

| KRAFT PAPER | 0.05m/m 0.08m/m 0.10m/m |

JYB-B2 | KLB | |

| XIAN PAPER | 0.05m/m 0.07m/m 0.10m/m |

JYB-B2 | XLB | |

| WATER NEEDIE CLOTH |

0.12m/m | JYB-B2 | WLB | |

| NOMEX(T411) | 0.13m/m | JYB-B2 | NLB |

REINFORCEMENT SPECIFICATION

| Raw Materials | Thickness | Name | Control Number | Sample |

|---|---|---|---|---|

| KRAFT PAPER JYB-B2 VARNISH |

0.05m/m 0.08m/m 0.10m/m 0.13m/m |

ARA | NK-01 |  |

| SILICON KRAFT PAPER JYB-B2 VARNISH) |

0.05m/m 0.08m/m 0.10m/m 0.13m/m |

AONV | NK-02 |  |

| ALUMINIUM JYB-B2 VARNISH |

0.05m/m 0.08m/m 0.10m/m 0.13m/m |

NK-03 |  |

|

| ALUMINIUM NV VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m |

NL | NK-04 |  |

| ALUMINIUM NV VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m 0.12m/m 0.15m/m 0.20m/m |

NNV | NK-05 |  |

| ALUMINIUM RA VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m 0.12m/m 0.15m/m 0.20m/m |

KL | NK-06 |  |

| ANODIZED ALUMINIUM NV VARNISH |

0.08m/m 0.10m/m 0.12m/m 0.15m/m 0.20m/m |

KNV | NK-07 |  |

| ANODIZED ALUMINIUM NV VARNISH |

0.08m/m 0.10m/m 0.12m/m 0.15m/m 0.20m/m |

KRA | NK-08 |  |

| NOMEX YB-B2 VARNISH |

0.05m/m 0.08m/m 0.13m/m |

AL | NK-09 |  |

| NOMEX NV VARNISH |

0.05m/m 0.08m/m 0.13m/m |

ANV | NK-10 |  |

| NOMEX RA VARNISH |

0.05m/m 0.08m/m 0.13m/m |

NRA | NK-11 |  |

| BRASS NV VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m |

CUNV | NK-12 |  |

| BRASS RA VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m |

CURA | NK-13 |  |

| PI(KAPTON) NV VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m 0.125m/m 0.15m/m 0.20m/m |

CNV | NK-14 |  |

| PI(KAPTON) RA VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m 0.125m/m 0.15m/m 0.20m/m |

CRA | NK-15 |  |

| GLASS FIBER SV VARNISH |

0.08m/m 0.125m/m 0.15m/m 0.20m/m |

TNV | NK-16 |  |

| GLASS FIBER RA VARNISH |

0.08m/m 0.125m/m 0.15m/m 0.20m/m |

TRA | NK-17 |  |

| KRAFT PAPER SILICON CONTAINING JYB-B2 VARNISH |

0.05m/m 0.08m/m | KPL | NK-18 |  |

| KRAFT PAPER SILICON CONTAINING NV VARNISH |

0.05m/m 0.08m/m 0.10m/m 0.13m/m |

KPNV | NK-19 |  |

| KRAFT PAPER SILICON CONTAINING RA VARNISH |

0.05m/m 0.08m/m 0.10m/m 0.13m/m |

KPRA | NK-20 |  |

| TITANIUM NV VARNISH |

0.05m/m 0.10m/m | TiNV | NK-21 |  |

| TITANIUM RA VARNISH |

0.05m/m 0.10m/m | TiRA | NK-22 |  |

| PI(KAPTON)SILICON CONTAINING NV VARNISH |

0.08m/m | CPNV | NK-23 |  |

| PI(KAPTON) SILICON CONTAINING RA VARNISH |

0.08m/m | CPRA | NK-24 |  |

| DURALUMIN JYB-B2 VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m |

DAL | NK-25 |  |

| DURALUMIN NV VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m |

DANV | NK-26 |  |

| DURALUMIN RA VARNISH |

0.03m/m 0.05m/m 0.08m/m 0.10m/m |

DARA | NK-27 |  |