Tinsel wire

Tinsel wire

Tinsel wire

Tinsel wire

Features of Nikkei's Tinsel wire

01

Nikkei's Tinsel Wires are made with a special anti-corrosive agent to prevent rusting.

02

We are always thinking and proposing products that meet the needs of our customers.

03

Nikkei's tinsel wire has excellent flexibility.

1.Types and Characteristics of Tinsel Wires for Voice Coil

Types of copper wire: tin alloyed copper, silver alloyed copper, silver-plated alloyed copper, etc.

Characteristics of various types of copper wire: Generally, tin alloy copper wire is used to manufacture brocade wire, but according to various requests from users, we use materials that take strength and electrical characteristics into consideration.

A silver alloy has a lower electrical resistance than a tin alloy and can be made into a product with high flexibility.

Plated products have good solderability and can reduce the time required for the soldering process.

2.Type of materials / CONEX, Kevlar, Blended spinning, etc.

Performance characteristics: Besides its purpose as a reinforcement, the performance of the center line is also an obstacle that has a large impact on the strength and especially the flexibility of the product, and we are responding to the needs of users with newly developed products.

The products made with Kevlar have higher strength and lower elongation.

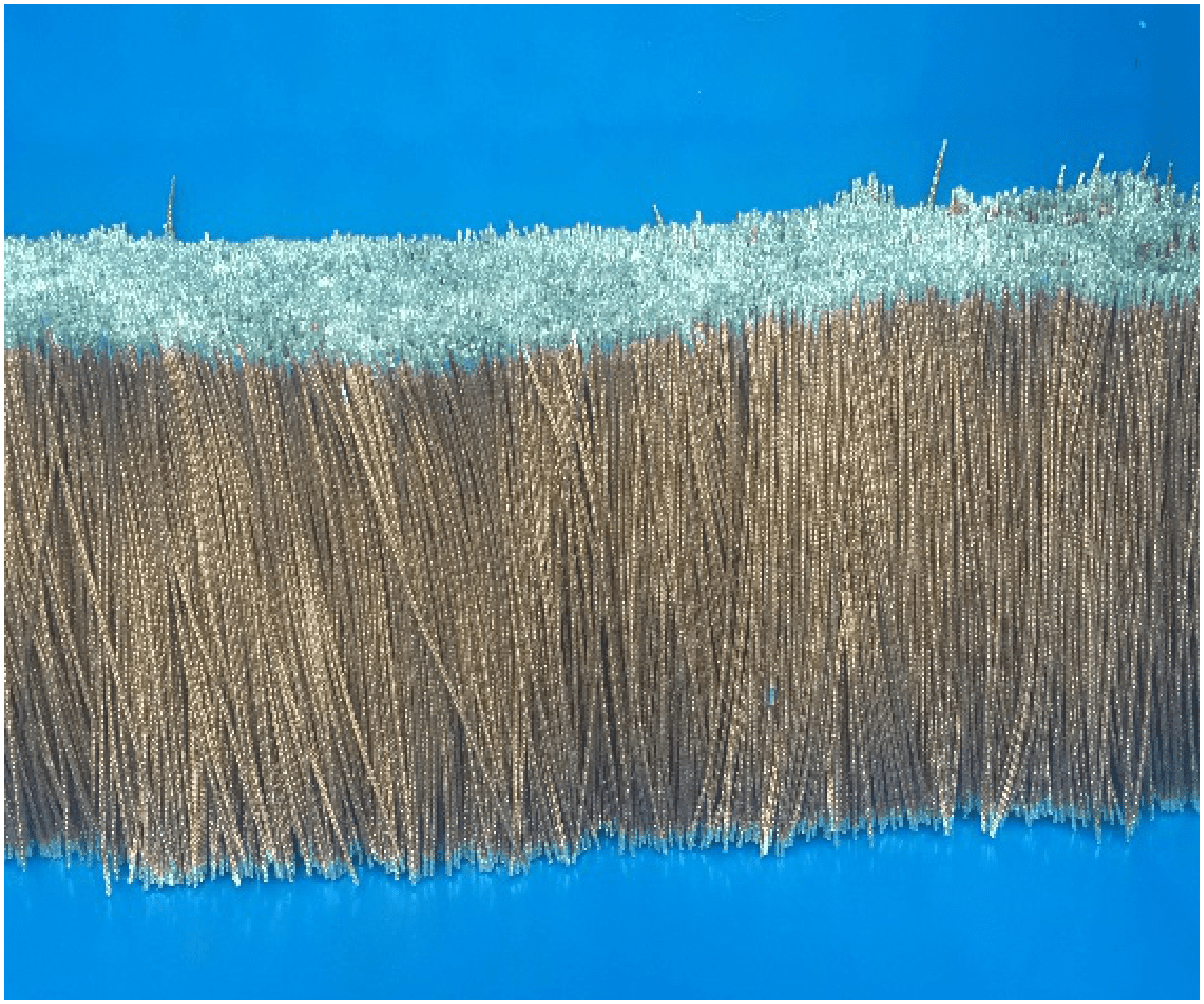

Single wire (silver plated / tin alloy / silver alloy)

N10S01060010W

N11S01020010W

Braided products (silver plated / tin alloy / silver alloy)

N10S0106B120W

N11S0102B120W

N10S0106BB160W

Assembly (silver plated / tin alloy / silver alloy)

N10S0106T160W

N11S0102T120W

Conductor yarn (aramid fiber with copper plating)

Packaging of soldered products at both ends of terminal (inspection/packaging)

Product before inspection

Finished product after inspection

Finished products out of the bale

Description of terminal packaging

The products, which are soldered at both ends of the lead wires, are individually packed in the quantity specified by the user, and then arranged in an orderly fashion in a special cardboard box for shipment.