Wire

Magnet wire

Magnet wire

Wire

1.Magnet wire model name and characteristics

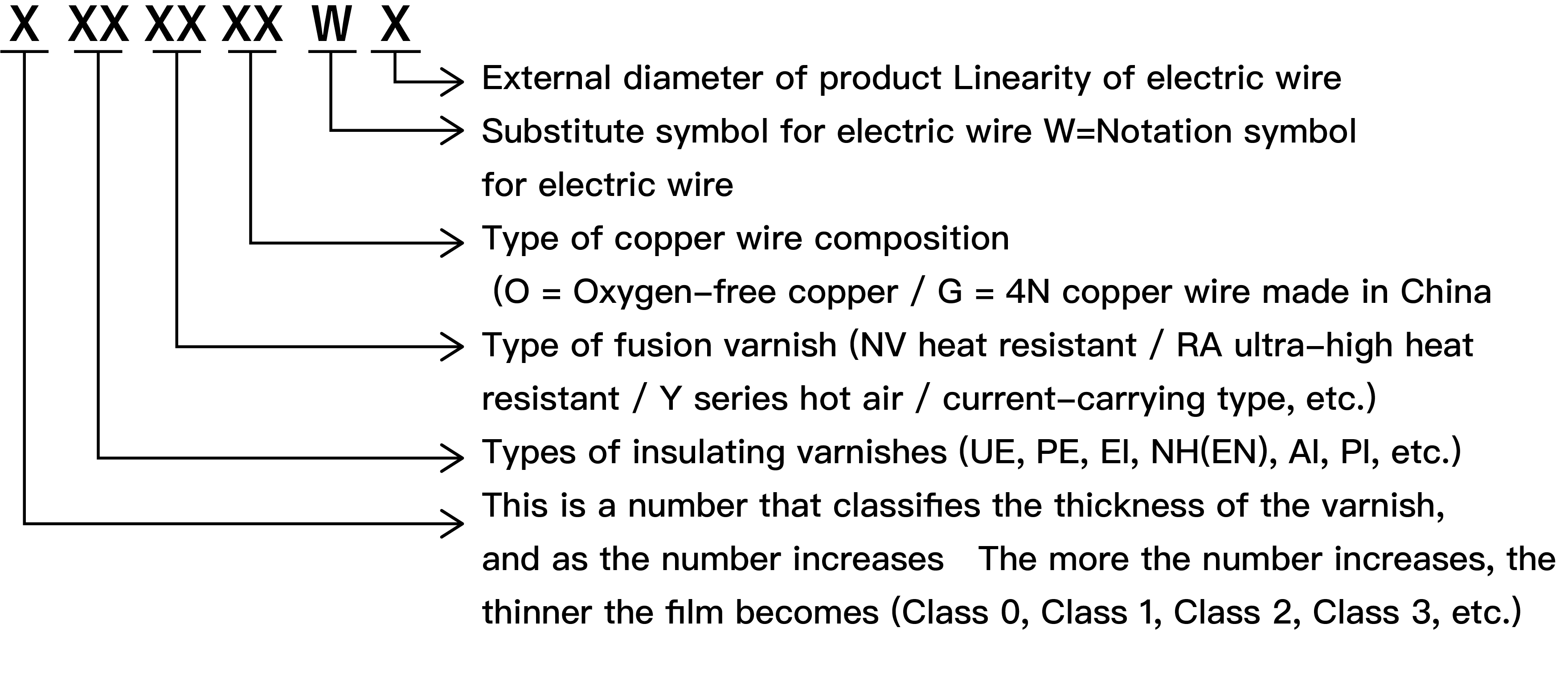

1.Model No.of magnetic wire made by NIKKEI

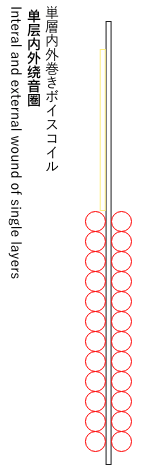

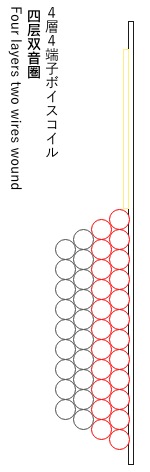

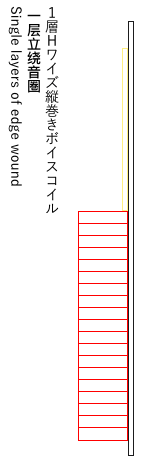

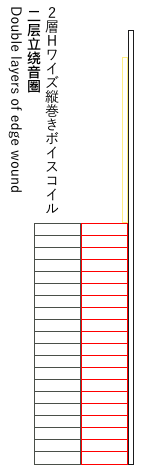

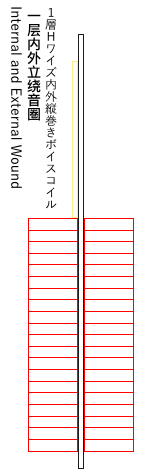

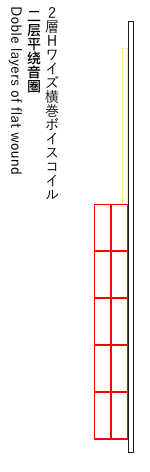

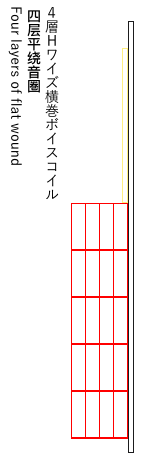

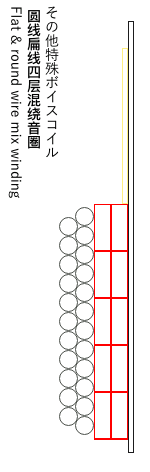

<Magnet Wire Structure>

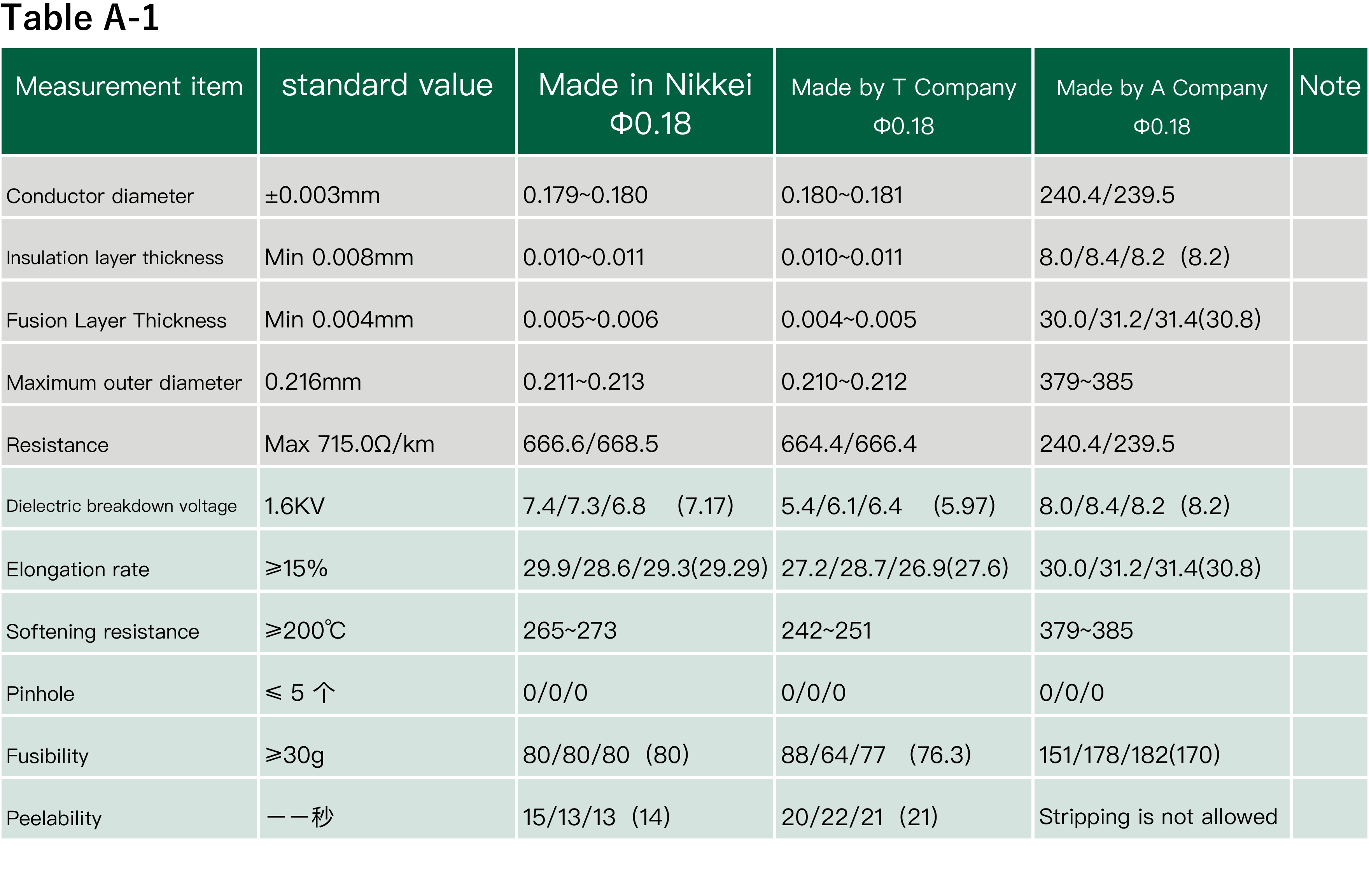

2.Wire characteristics

The heat resistance temperature of the varnish used for PENV(O)W is in the 155°C class.

Compared to other companies, Nikkay's wires have higher breakdown voltage, elongation rate,

softening resistance, and bonding properties.

They are also easy to peel off and have excellent workability.

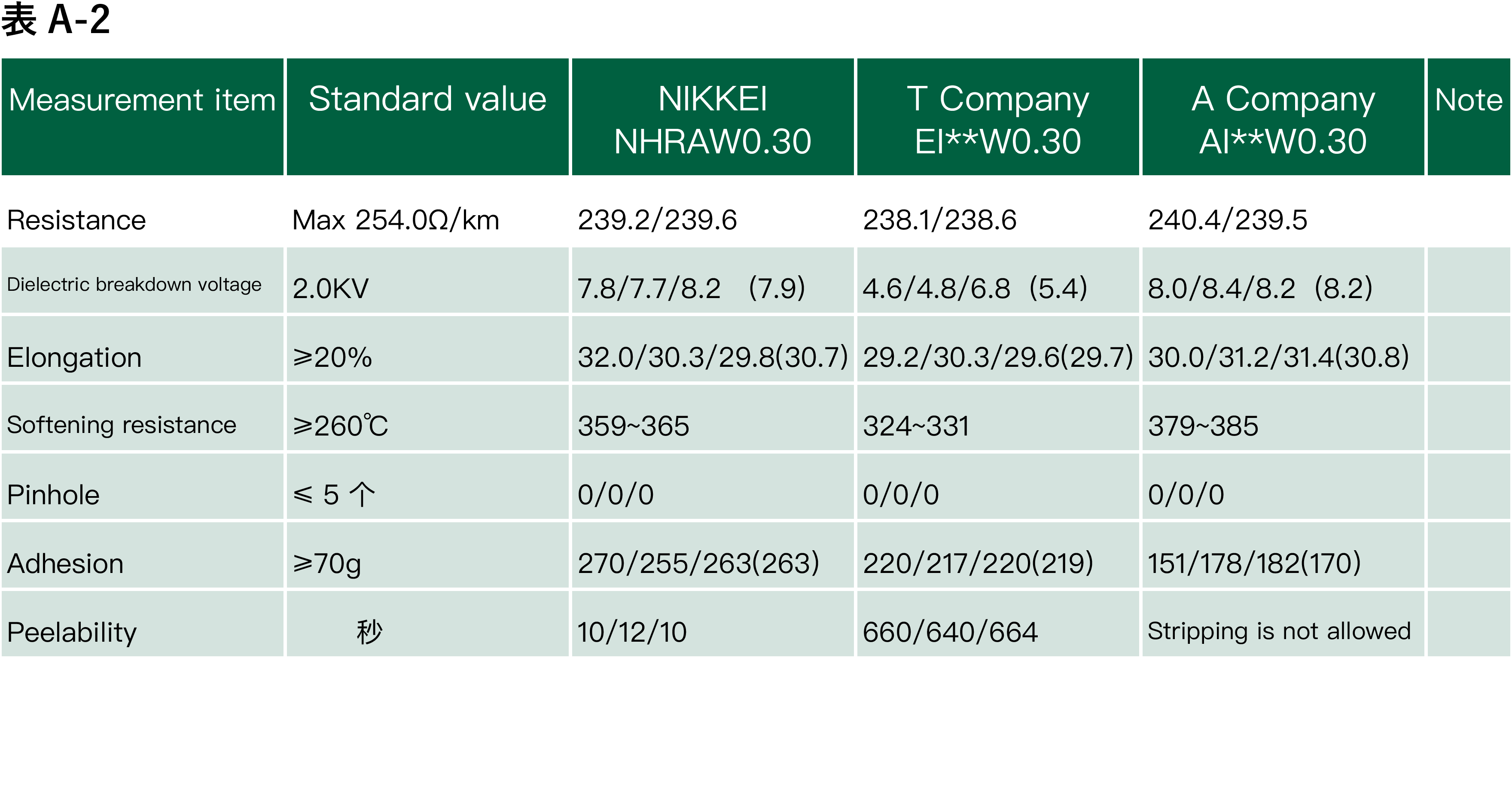

NH(EN)RA(O)W is an ultra-high heat-resistant magnet wire developed independently by Nikkei Electric Co.

NH(EN)RA(O)W is an ultra-high heat-resistant magnet wire developed by Nikkei Electric Co.

The heat resistance temperature is equivalent to UL standard 210°C, which is between EI and AI.

EN insulating varnish and RA fusion varnish (fusion varnish with a higher heat resistance temperature than NV) are special varnishes.

In addition to improving the heat resistance temperature of the insulating varnish used for NH(EN)RA(O)W magnet wire, Nikkei Electric has also improved the heat resistance temperature of the fusion varnish.

(See Test Table A-2 for a detailed comparison of the performance of Nikke Electric's NH(EN)RA(O)W 0.30 and other manufacturers' EI and AI magnet wires.

The breakdown voltage, elongation rate, and softening resistance of Nikkay's magnet wire are equivalent to those of other companies.

As a feature, it is a product with high fusibility, very good peelability, and good workability.

EN(NH)RA(O)W is a high heat resistant magnet wire developed by Nikkei.

EN(NH)RA(O)W is a high heat resistant magnetic wire developed by Nikkei.

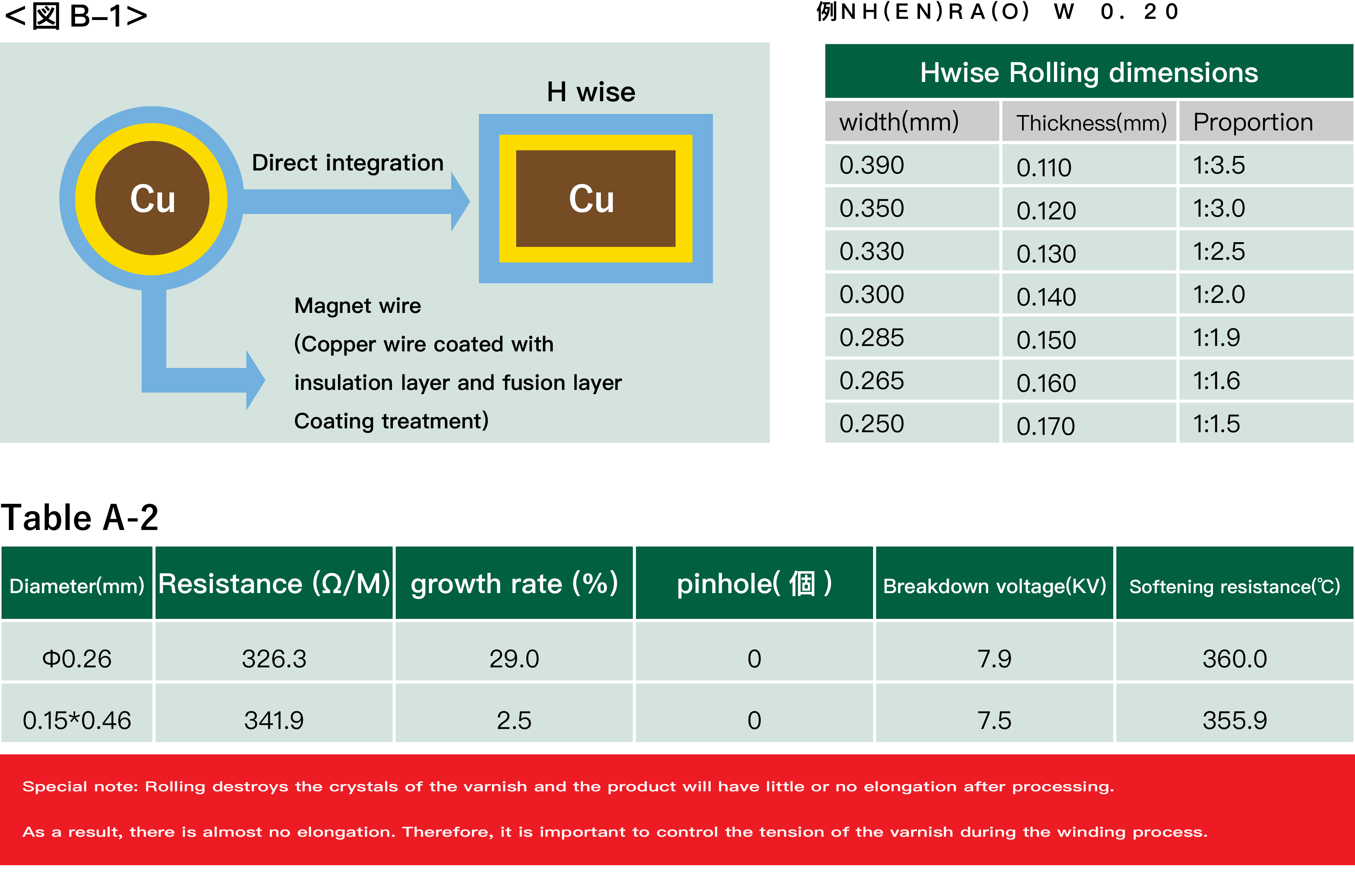

It has excellent flexibility and elongation, and can be rolled into round wire.

H-wire or square wire can be produced by rolling according to the customer's needs. (See B-1)

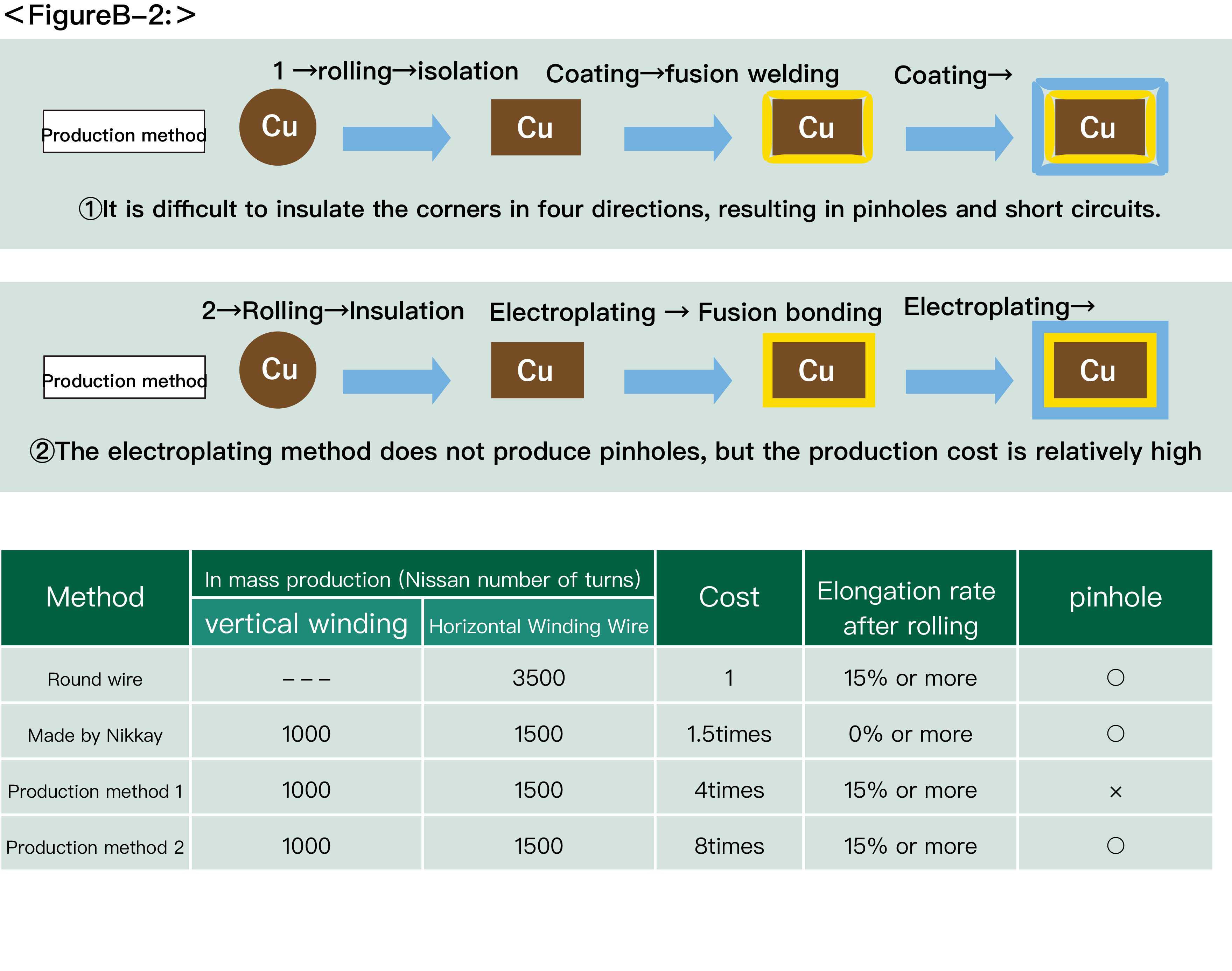

Other companies' H-wise production methods(FigureB-2)

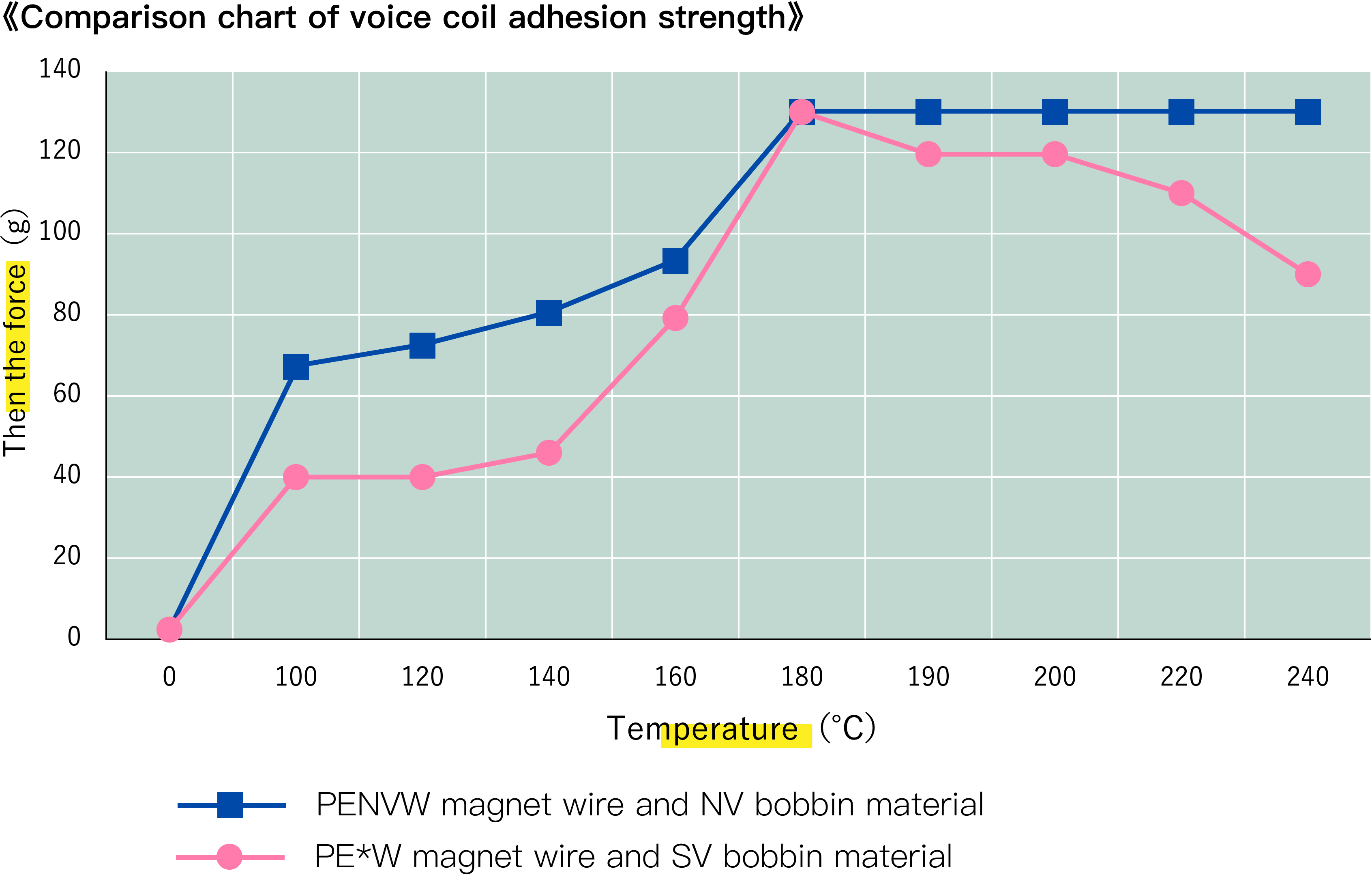

Comparison of voice coil using PENVW magnet wire and NV bobbin material produced by Nikkay and Comparison with a combination of PE*W and SV bobbin produced by another company.

2.Properties of EN Varnish for Heat Resistant Electric Wires

Features:

1. Heat-resistant insulation material equivalent to H-class.

2. Good compatibility with impregnation coating tools.

3. The most important feature is that the film peeling property is very good.

Leading-out mode

-

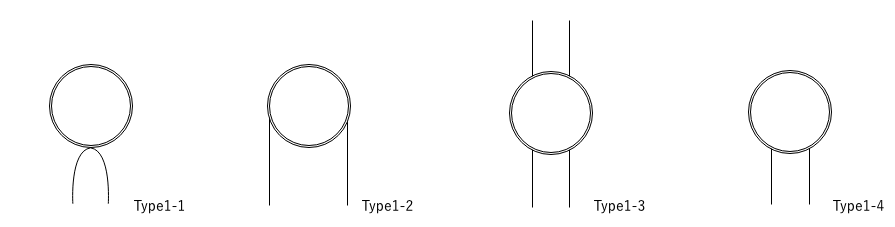

Type-1

-

Type-2

-

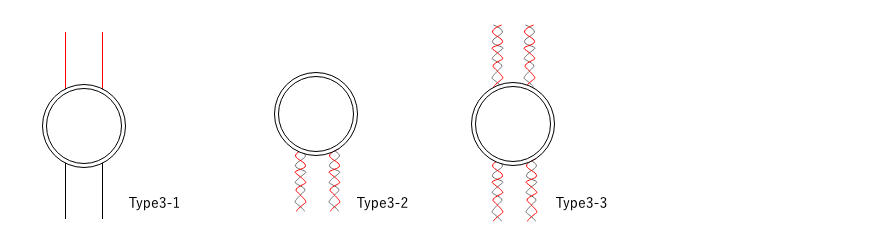

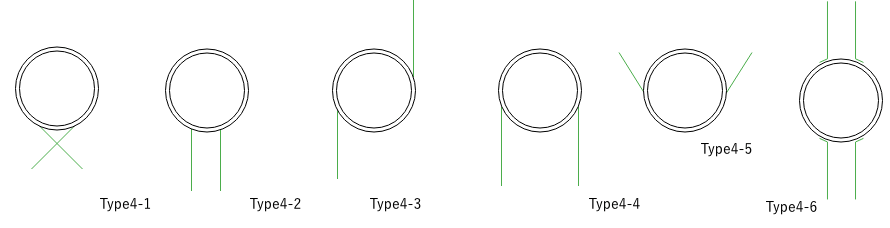

Type-3

-

Type-4

-

Type-5

-

Type-6

-

Type-7

-

Type-8

-

Type-9

-

Type-10

-

Type-11

-

Type-12

Leading-out mode

-

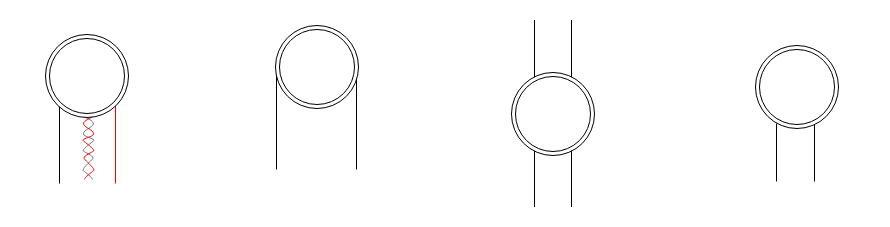

2-layer voice coil leading-out mode

-

4-layer voice coil leading-out mode

-

Dual voice coil leading-out mode

-

Welded braided wire voice coil leading-out mode

マグネットワイヤーの種類

一. 一般マグネットワイヤーGeneral Magnet Wires

- 1. PEW ポリエステルエナメル銅線 Polyester enameled copper wire

- 2. EIW ポリエステルイミドエナメル銅線 Polyester-imide enameled copper wire

- 3. AIW ポリアミドイミドエナメル銅線 Polyamide-imide enameled copper wire

- 4. 一般マグネットワイヤー比較表 Comparative table-General Magnet Wire

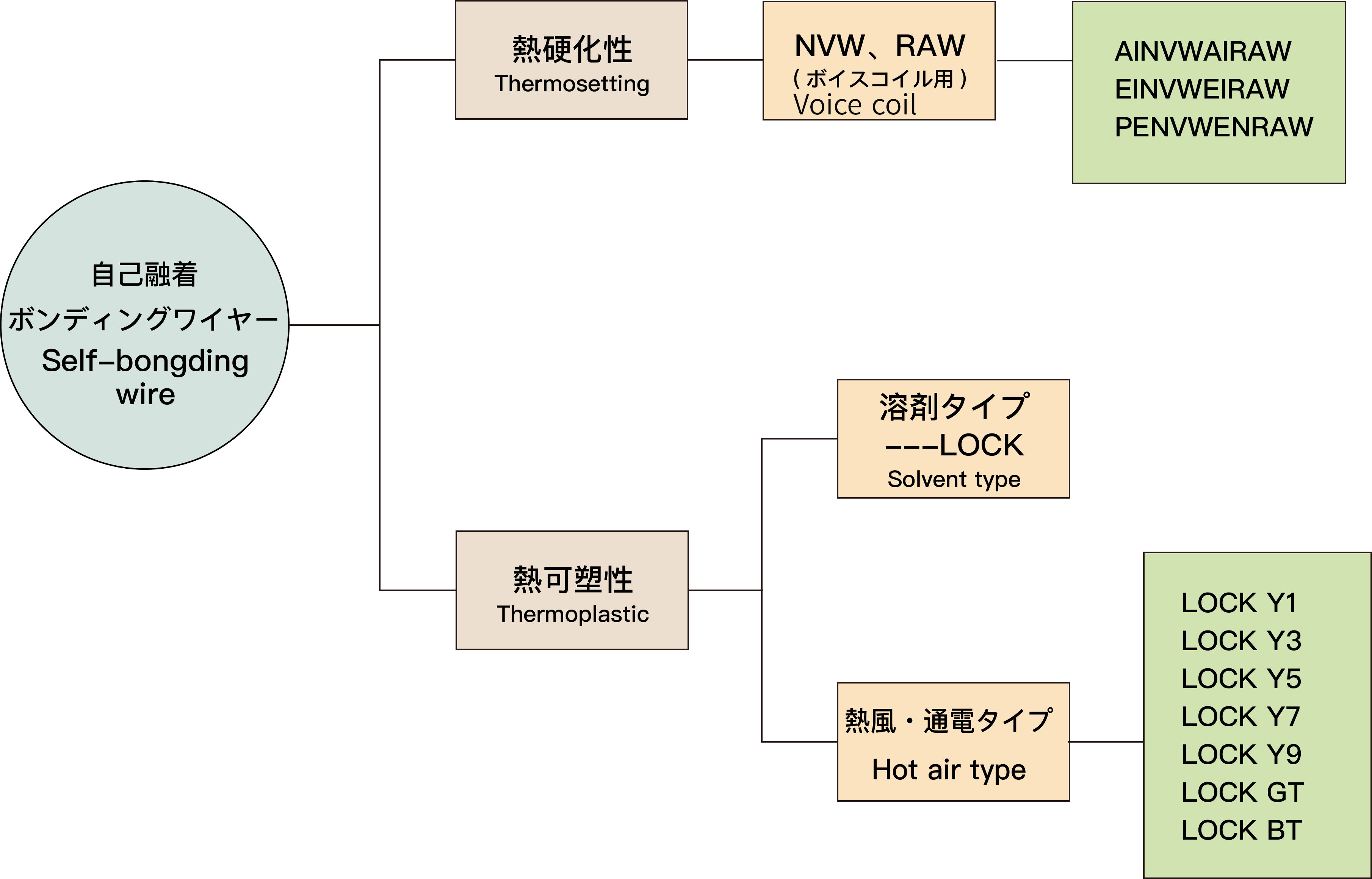

二. 自己融着マグネットワイヤーSelf-Bonding Magnet Wires

- 1. NVW、RAW 熱硬化型 Thermosetting type

- 2. LOCK 溶剤型 Solvent type

- 3. LOCK Y1自己滑生熱風型 Smooth surface ,hot air type

- 4. LOCK Y3自己滑生高温熱風、通電型 Smooth surface,high temperature hot air,electric current type

- 5. LOCK Y5自己滑生高温熱風、通電型 Smooth surface,high temperature hot air,electric current type

- 6. LOCK Y7自己滑生高温熱風、通電型 Smooth surface,high temperature hot air,electric current type

- 7. LOCK Y9自己滑生高温熱風、通電型 Smooth surface,high temperature hot air,electric current type

- 8. 自己融着マグネットワイヤー特性比較表 Comparative table self-bonding magnet wires

三. 特殊マグネットワイヤーSpecial Magnet Wires

- 1. HT20W 高張力マグネットワイヤー High tension magnet wire

- 2. HT40W 超高張力マグネットワイヤー Super high tension magnet wire

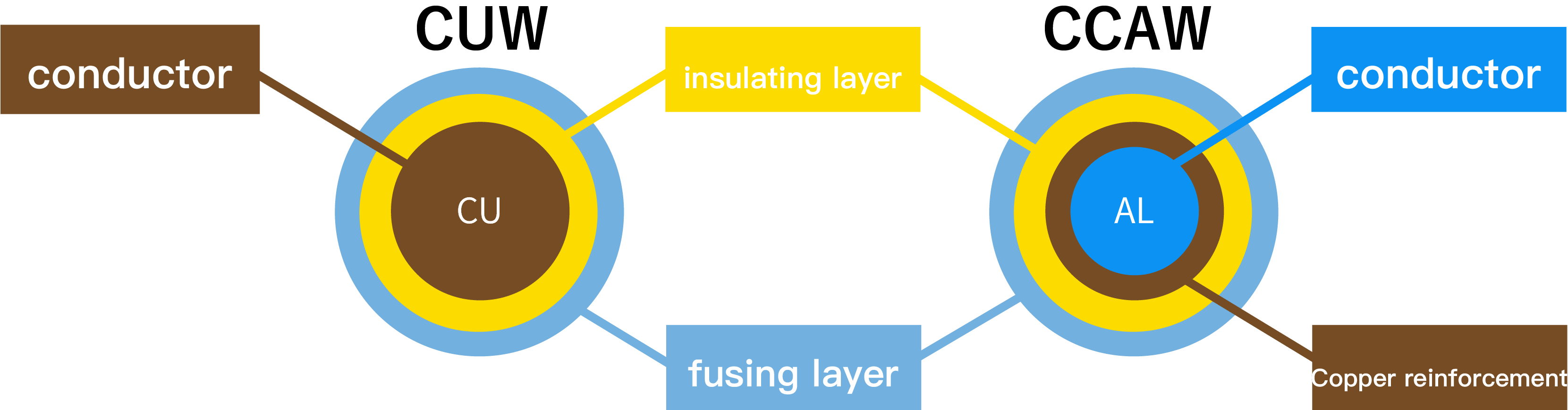

- 3. CCAW 銅クラッドアルミ線 Copper-clad aluminum wire

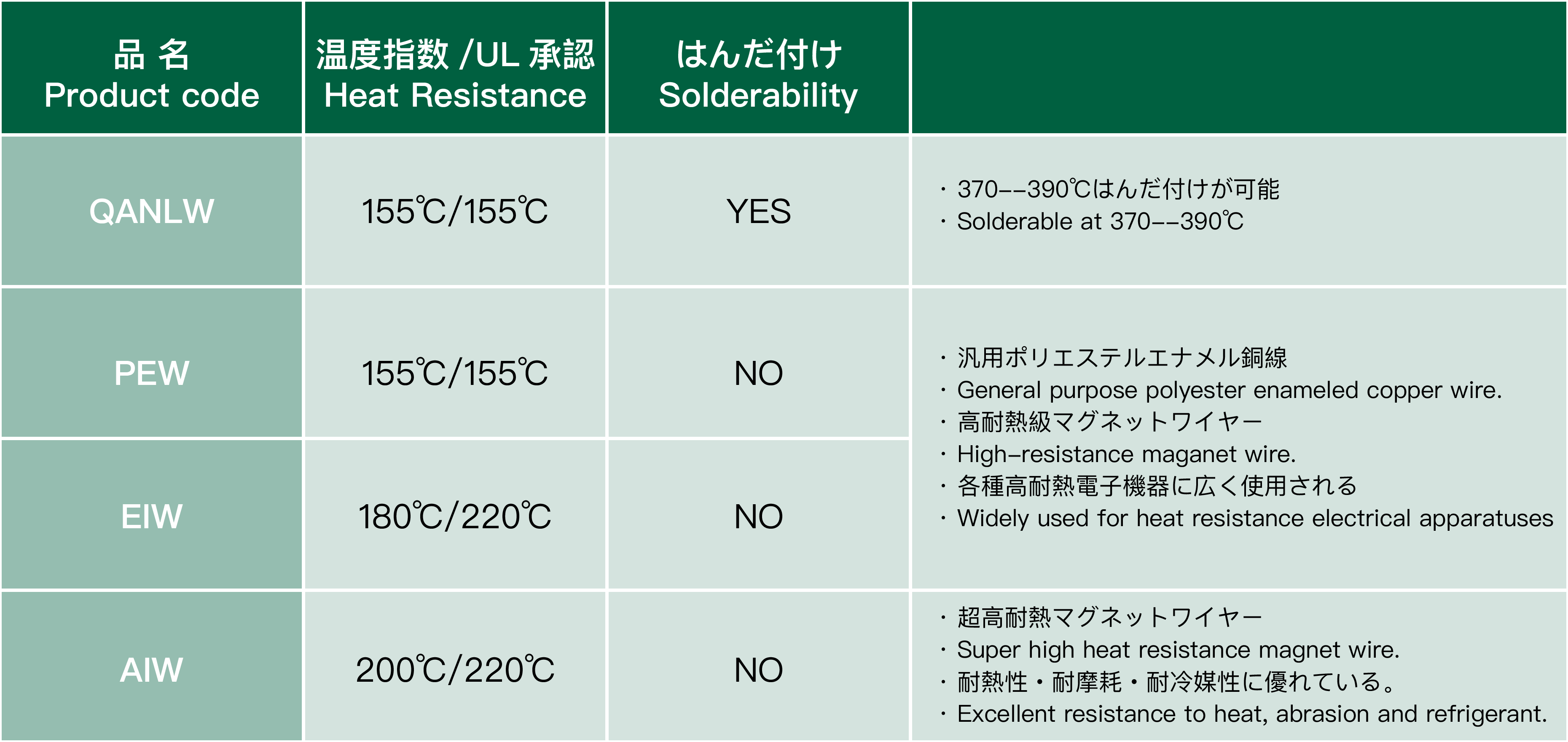

一般マグネットワイヤー General Magnet Wires

QANLW 直接半田可能マグネットワイヤーSolderable Enameled Copper Wire

● 特徴 Features

- ① 耐熱性はポリウレタンとポリエステルの間 Heat resistance between polyurethan and polyester;

- ② 380度半田可能 Solderable at 380℃

- ③ 着色可能 Colorable

- ① 適用規格: JCS 394半田付け可能なエナメル銅線Applicable standards:JCS 394 Solderable enameled round copper winding wires

- ② 用途:小型モータ、各種小型変圧器、リレーコイルApplications: small motors,small transformers for electronic equipment,relay coils.

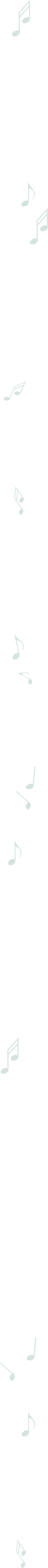

- ③ 温度指数及び製造範囲

PEW ポリエステルマグネットワイヤーPolyster Enameled Copper Wire

● 特徴 Features

- ① 耐溶剤に優れている copper winding wires";Excellent resistance to solvents.

- ② 耐水性が悪く、密閉装置での使用には注意が必要です。 Low resistance to ydrolysis. Care should be taken when applying to

- ① 適用基準:JIS C 3202ポリエステルエナメル銅線 Applicable atandards:JIS C3202 "Polyester enameled round

- ② 用途:汎用モーター・携帯式電動機・変圧器・リレーコイル ソレノイド、ソレノイド・リレーコイル。Applications: General purpose motors,protable generators,transformers, solenoid, relay coils.

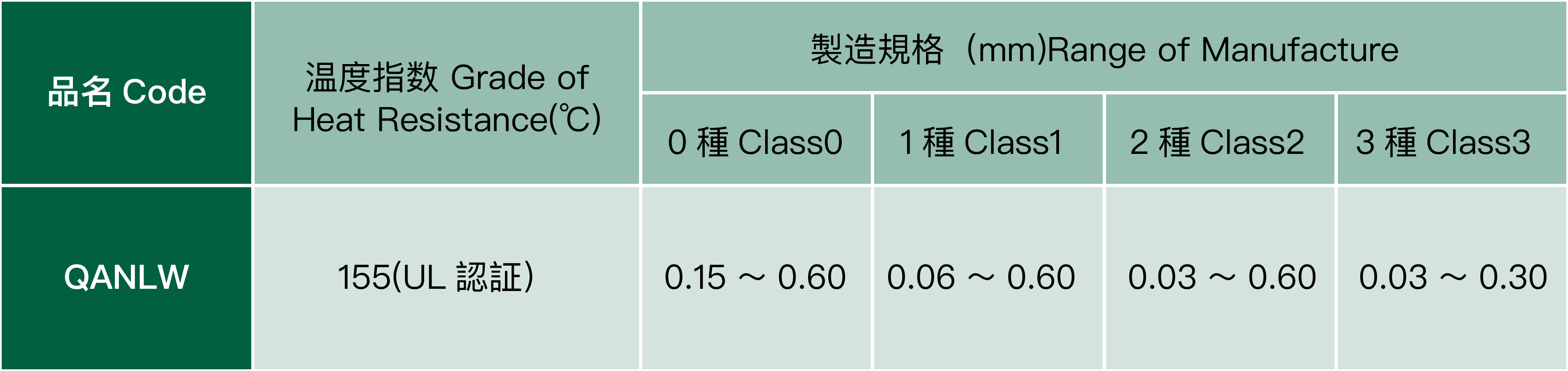

- ③ 温度指数及び製造範囲

EIW ポリアミドイミドマグネットワイヤーPolyester-imide Enameled Copper Wire

● 特徴 Features

- ① 電気性、化学性、機械性に優れている。 Excellent electrical,chemical and me-chanical properties;

- ② 耐熱180度を必要とする電気機器に広く使用している。 Heat resistant up to 180℃, Widely used for electrical apparatuses which requires heat resistance;

- ③ 亀裂が発生する可能性があります。May develop crazing.

- ① 適用規格:JIS C 3202ポリエステルイミドエナメル銅線 Applicable standards:JIS C3202"Polyesterimide enameled round copper winding wires".

- ② 用途:耐熱汎用電動機、変圧器、自動車部品Applications: Heat-resistant general-purpose motors,transformers,automotive parts.

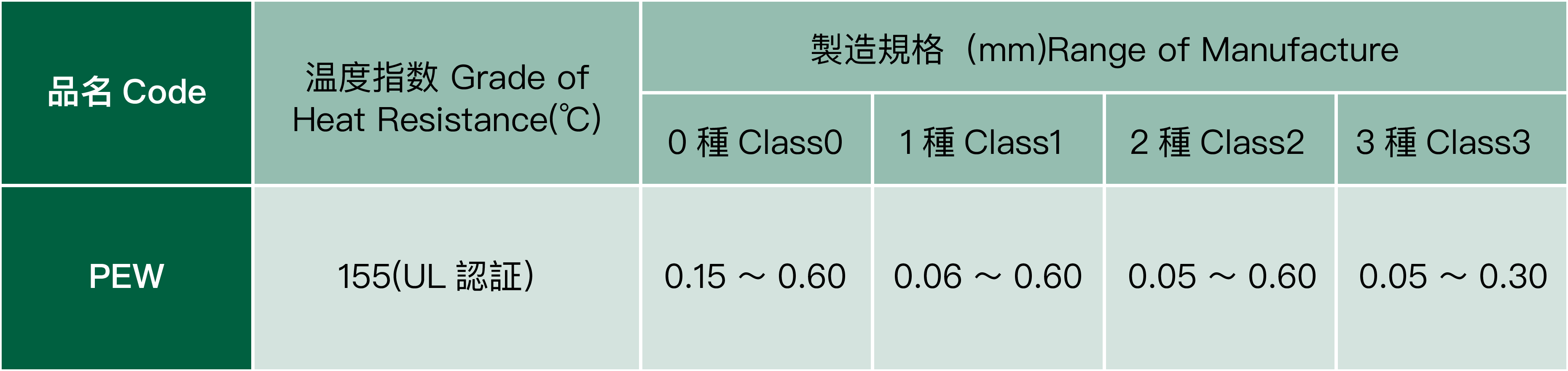

- ③ 温度指数及び製造範囲

AIW ポリアミドイミドエナメル線Polyamide-imide Enameled Copper Wire

● 特徴 Features

- ① EIWよりも耐熱、耐摩耗、耐冷媒性に優れています。Higher resistance to heat,abr-asion and refrigerants than those of EIW wire.

- ② 耐熱200度の過負荷に耐える優れた製品で、各種耐熱性が必要な電子部品に適しています。With heat resistance up to 200℃ a-nd high resistance to overload, the wire can be safely used for electrical apparatus which is requires heat-resistance.

- ① JCS 334「ポリアミドイミドエナメル銅線Applicable standards:JCS 334"polyamideimide enamelad round copper winding wires".

- ② 用 途:用途:高耐熱モーター、電動工具、耐高温乾式変圧器、電磁弁Applications: Heat-resistance motors, motors for electric tools,heat-resistance dry type transformers, lifting magnet coils.

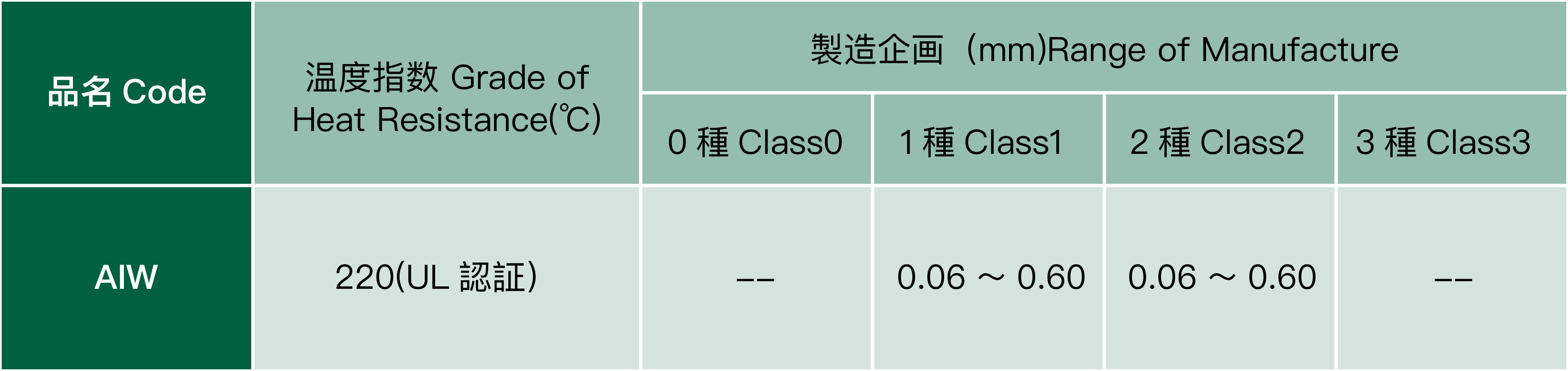

- ③温度指数及び製造範囲

一般マグネットワイヤー比較表

Comparative Table - General Magnet Wires

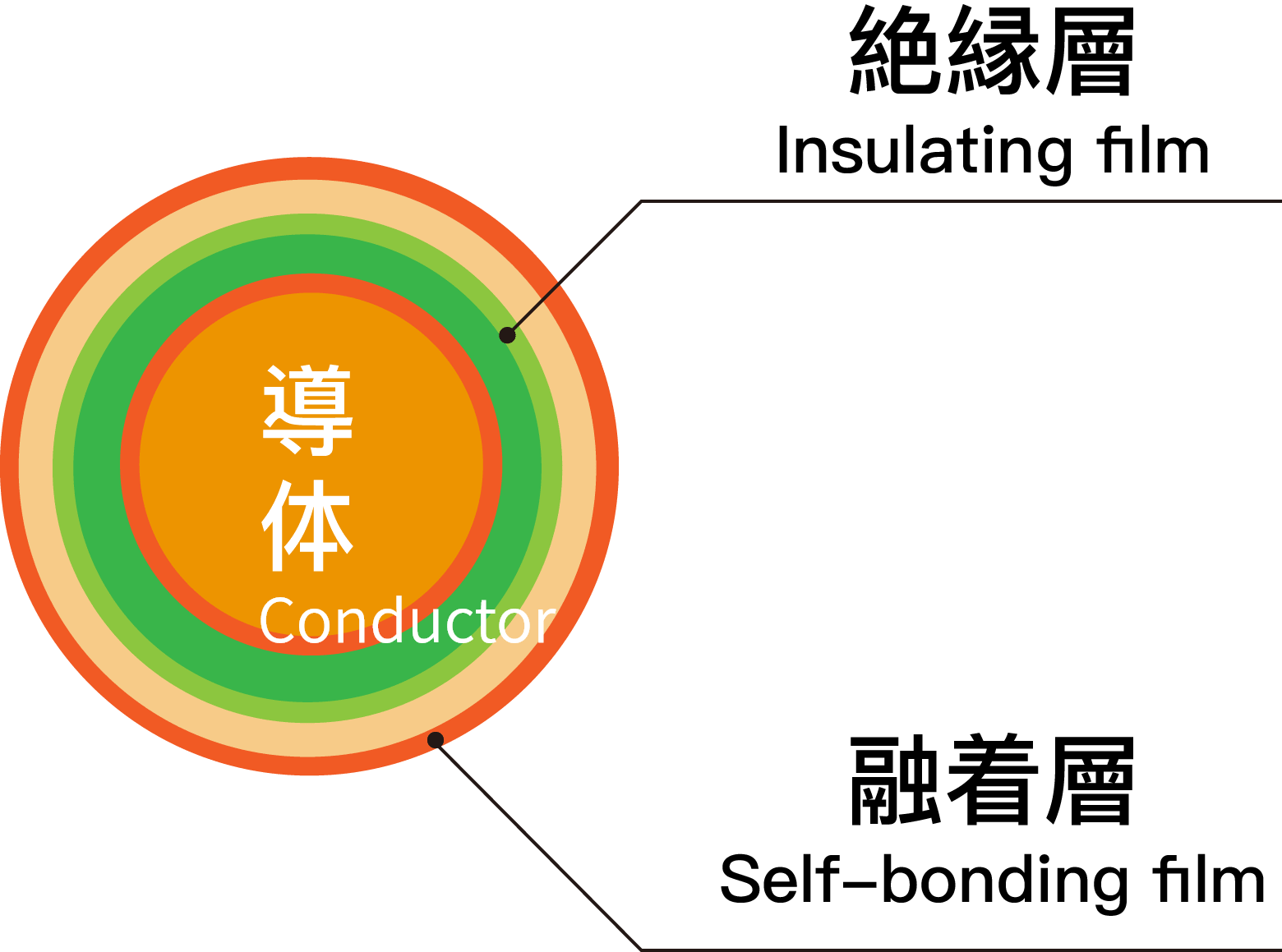

構造Structure

自己融着マグネットワイヤーは二層のコーティングで形成されています。

絶縁層の外層にもう一層に熱可塑性をコーティングする製品で、熱硬化絶縁皮膜型、又はその他の材質の自己融着コーティングがあります。

絶縁層は通常はポリウレタンですが、弊社は、ポリエステルなどの類似した材料を各種生産しており、融着層と絶縁層をベストに組み合わせ、顧客のニーズに合わせたオリジナルボンディングワイヤーを提供します。

The self-bonding magnet wire is a double layered copper conductor covered with a layer of self-bonding film auch as thermoplastic resin or other materical over a layerof insulating film such as polyurethane,polyeater or similar material.

We manufacture a wide variety of self-bonding wires by expertly combining the bonding layer with the insulating film to meet customers' need.

分類Classification of bonding layers

※熱硬化型は、ボイスコイルを巻いた後に2次加熱処理を施す事により、熱硬化性皮膜が高い耐熱接着力を発揮した製品に仕上がります。

After winding, the coil heated to change its thermosetting film into a thermally stable three-dimensional structure.

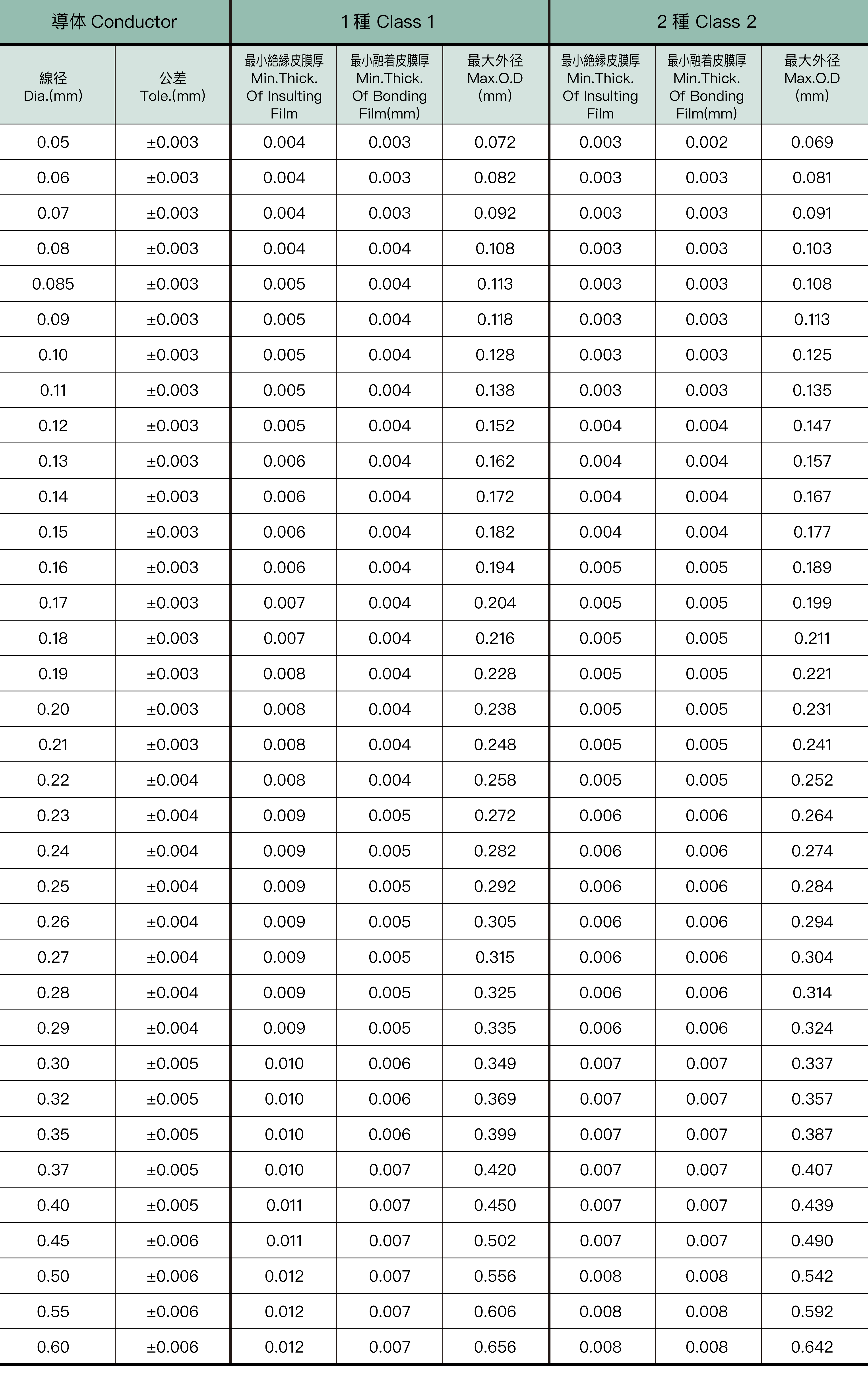

●熱硬化型自己融着ボンディングワイヤー寸法表(NVW、RAW)Size of Thermelsetting Self-Bonding Magnet Wires(NVW、RAW)